Page 250 - Handbook of Adhesives and Sealants

P. 250

Surfaces and Surface Preparation 219

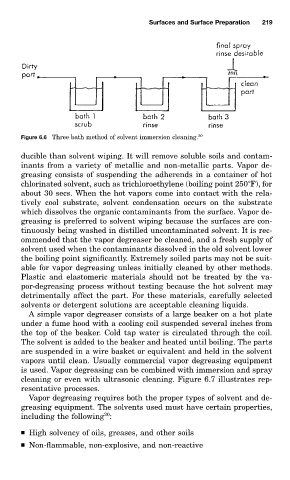

Figure 6.6 Three bath method of solvent immersion cleaning. 20

ducible than solvent wiping. It will remove soluble soils and contam-

inants from a variety of metallic and non-metallic parts. Vapor de-

greasing consists of suspending the adherends in a container of hot

chlorinated solvent, such as trichloroethylene (boiling point 250 F), for

about 30 secs. When the hot vapors come into contact with the rela-

tively cool substrate, solvent condensation occurs on the substrate

which dissolves the organic contaminants from the surface. Vapor de-

greasing is preferred to solvent wiping because the surfaces are con-

tinuously being washed in distilled uncontaminated solvent. It is rec-

ommended that the vapor degreaser be cleaned, and a fresh supply of

solvent used when the contaminants dissolved in the old solvent lower

the boiling point significantly. Extremely soiled parts may not be suit-

able for vapor degreasing unless initially cleaned by other methods.

Plastic and elastomeric materials should not be treated by the va-

por-degreasing process without testing because the hot solvent may

detrimentally affect the part. For these materials, carefully selected

solvents or detergent solutions are acceptable cleaning liquids.

A simple vapor degreaser consists of a large beaker on a hot plate

under a fume hood with a cooling coil suspended several inches from

the top of the beaker. Cold tap water is circulated through the coil.

The solvent is added to the beaker and heated until boiling. The parts

are suspended in a wire basket or equivalent and held in the solvent

vapors until clean. Usually commercial vapor degreasing equipment

is used. Vapor degreasing can be combined with immersion and spray

cleaning or even with ultrasonic cleaning. Figure 6.7 illustrates rep-

resentative processes.

Vapor degreasing requires both the proper types of solvent and de-

greasing equipment. The solvents used must have certain properties,

20

including the following :

High solvency of oils, greases, and other soils

Non-flammable, non-explosive, and non-reactive