Page 265 - Handbook of Adhesives and Sealants

P. 265

Surfaces and Surface Preparation 233

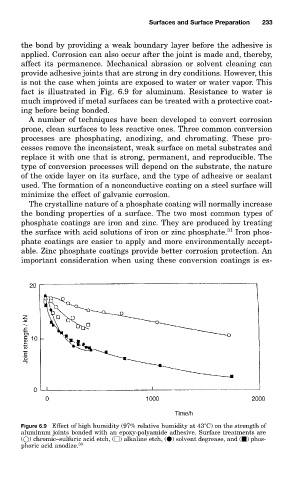

the bond by providing a weak boundary layer before the adhesive is

applied. Corrosion can also occur after the joint is made and, thereby,

affect its permanence. Mechanical abrasion or solvent cleaning can

provide adhesive joints that are strong in dry conditions. However, this

is not the case when joints are exposed to water or water vapor. This

fact is illustrated in Fig. 6.9 for aluminum. Resistance to water is

much improved if metal surfaces can be treated with a protective coat-

ing before being bonded.

A number of techniques have been developed to convert corrosion

prone, clean surfaces to less reactive ones. Three common conversion

processes are phosphating, anodizing, and chromating. These pro-

cesses remove the inconsistent, weak surface on metal substrates and

replace it with one that is strong, permanent, and reproducible. The

type of conversion processes will depend on the substrate, the nature

of the oxide layer on its surface, and the type of adhesive or sealant

used. The formation of a nonconductive coating on a steel surface will

minimize the effect of galvanic corrosion.

The crystalline nature of a phosphate coating will normally increase

the bonding properties of a surface. The two most common types of

phosphate coatings are iron and zinc. They are produced by treating

the surface with acid solutions of iron or zinc phosphate. 31 Iron phos-

phate coatings are easier to apply and more environmentally accept-

able. Zinc phosphate coatings provide better corrosion protection. An

important consideration when using these conversion coatings is es-

Figure 6.9 Effect of high humidity (97% relative humidity at 43 C) on the strength of

aluminum joints bonded with an epoxy-polyamide adhesive. Surface treatments are

( ) chromic–sulfuric acid etch, ( ) alkaline etch, ( ) solvent degrease, and ( ) phos-

phoric acid anodize. 30