Page 297 - Handbook of Adhesives and Sealants

P. 297

262 Chapter Seven

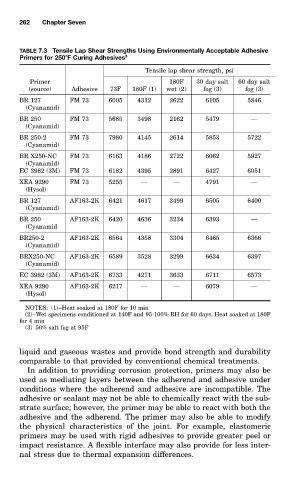

TABLE 7.3 Tensile Lap Shear Strengths Using Environmentally Acceptable Adhesive

Primers for 250 F Curing Adhesives 3

Tensile lap shear strength, psi

Primer 180F 30 day salt 60 day salt

(source) Adhesive 73F 180F (1) wet (2) fog (3) fog (3)

BR 127 FM 73 6005 4312 2622 6105 5846

(Cyanamid)

BR 250 FM 73 5685 3498 2162 5479 —

(Cyanamid)

BR 250-2 FM 73 7980 4145 2614 5853 5722

(Cyanamid)

BR X250-NC FM 73 6163 4186 2722 6062 5927

(Cyanamid)

EC 3982 (3M) FM 73 6182 4395 2891 6427 6051

XEA 9290 FM 73 5255 — — 4791 —

(Hysol)

BR 127 AF163-2K 6421 4617 3499 6505 6400

(Cyanamid)

BR 250 AF163-2K 6420 4636 3234 6393 —

(Cyanamid

BR250-2 AF163-2K 6564 4358 3304 6465 6366

(Cyanamid)

BRX250-NC AF163-2K 6589 3528 3299 6634 6397

(Cyanamid)

EC 3982 (3M) AF163-2K 6733 4271 3633 6711 6573

XEA 9290 AF163-2K 6217 — — 6079 —

(Hysol)

NOTES: (1)–Heat soaked at 180F for 10 min

(2)–Wet specimens conditioned at 140F and 95-100% RH for 60 days. Heat soaked at 180F

for 4 min

(3) 50% salt fog at 95F

liquid and gaseous wastes and provide bond strength and durability

comparable to that provided by conventional chemical treatments.

In addition to providing corrosion protection, primers may also be

used as mediating layers between the adherend and adhesive under

conditions where the adherend and adhesive are incompatible. The

adhesive or sealant may not be able to chemically react with the sub-

strate surface; however, the primer may be able to react with both the

adhesive and the adherend. The primer may also be able to modify

the physical characteristics of the joint. For example, elastomeric

primers may be used with rigid adhesives to provide greater peel or

impact resistance. A flexible interface may also provide for less inter-

nal stress due to thermal expansion differences.