Page 502 - Handbook of Adhesives and Sealants

P. 502

434 Chapter Eleven

strength to most elastomers. Surface treatment consists of washing

with a solvent, abrading, or acid cyclizing as described in Appendix

C-3.

Elastomers vary greatly in their formulation from one manufacturer

to another. Fillers, plasticizers, antioxidants, and other components

may affect the adhesive bond. Adhesives should be thoroughly tested

with a specific elastomer and then reevaluated if the elastomer man-

ufacturer or formulation is changed even though the physical property

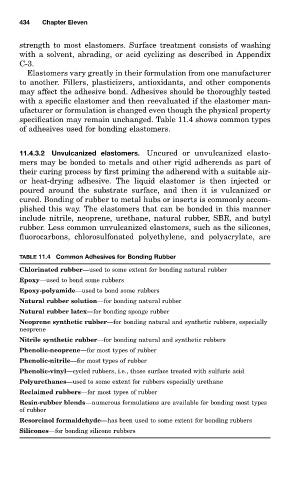

specification may remain unchanged. Table 11.4 shows common types

of adhesives used for bonding elastomers.

11.4.3.2 Unvulcanized elastomers. Uncured or unvulcanized elasto-

mers may be bonded to metals and other rigid adherends as part of

their curing process by first priming the adherend with a suitable air-

or heat-drying adhesive. The liquid elastomer is then injected or

poured around the substrate surface, and then it is vulcanized or

cured. Bonding of rubber to metal hubs or inserts is commonly accom-

plished this way. The elastomers that can be bonded in this manner

include nitrile, neoprene, urethane, natural rubber, SBR, and butyl

rubber. Less common unvulcanized elastomers, such as the silicones,

fluorocarbons, chlorosulfonated polyethylene, and polyacrylate, are

TABLE 11.4 Common Adhesives for Bonding Rubber

Chlorinated rubber—used to some extent for bonding natural rubber

Epoxy—used to bond some rubbers

Epoxy-polyamide—used to bond some rubbers

Natural rubber solution—for bonding natural rubber

Natural rubber latex—for bonding sponge rubber

Neoprene synthetic rubber—for bonding natural and synthetic rubbers, especially

neoprene

Nitrile synthetic rubber—for bonding natural and synthetic rubbers

Phenolic-neoprene—for most types of rubber

Phenolic-nitrile—for most types of rubber

Phenolic-vinyl—cycled rubbers, i.e., those surface treated with sulfuric acid

Polyurethanes—used to some extent for rubbers especially urethane

Reclaimed rubbers—for most types of rubber

Resin-rubber blends—numerous formulations are available for bonding most types

of rubber

Resorcinol formaldehyde—has been used to some extent for bonding rubbers

Silicones—for bonding silicone rubbers