Page 546 - Handbook of Adhesives and Sealants

P. 546

Sealant Classification and Composition 471

Before

Foam-in Preformed

place gasket gasket

After

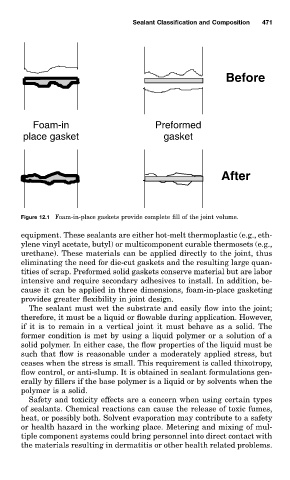

Figure 12.1 Foam-in-place gaskets provide complete fill of the joint volume.

equipment. These sealants are either hot-melt thermoplastic (e.g., eth-

ylene vinyl acetate, butyl) or multicomponent curable thermosets (e.g.,

urethane). These materials can be applied directly to the joint, thus

eliminating the need for die-cut gaskets and the resulting large quan-

tities of scrap. Preformed solid gaskets conserve material but are labor

intensive and require secondary adhesives to install. In addition, be-

cause it can be applied in three dimensions, foam-in-place gasketing

provides greater flexibility in joint design.

The sealant must wet the substrate and easily flow into the joint;

therefore, it must be a liquid or flowable during application. However,

if it is to remain in a vertical joint it must behave as a solid. The

former condition is met by using a liquid polymer or a solution of a

solid polymer. In either case, the flow properties of the liquid must be

such that flow is reasonable under a moderately applied stress, but

ceases when the stress is small. This requirement is called thixotropy,

flow control, or anti-slump. It is obtained in sealant formulations gen-

erally by fillers if the base polymer is a liquid or by solvents when the

polymer is a solid.

Safety and toxicity effects are a concern when using certain types

of sealants. Chemical reactions can cause the release of toxic fumes,

heat, or possibly both. Solvent evaporation may contribute to a safety

or health hazard in the working place. Metering and mixing of mul-

tiple component systems could bring personnel into direct contact with

the materials resulting in dermatitis or other health related problems.