Page 440 - Handbook of Biomechatronics

P. 440

434 Graham Brooker

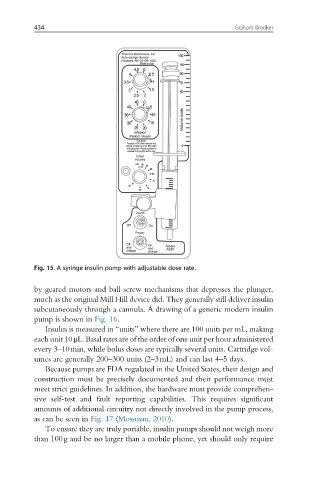

Fig. 15 A syringe insulin pump with adjustable dose rate.

by geared motors and ball screw mechanisms that depresses the plunger,

much as the original Mill Hill device did. They generally still deliver insulin

subcutaneously through a cannula. A drawing of a generic modern insulin

pump is shown in Fig. 16.

Insulin is measured in “units” where there are 100 units per mL, making

each unit 10μL. Basal rates are of the order of one unit per hour administered

every 3–10min, while bolus doses are typically several units. Cartridge vol-

umes are generally 200–300 units (2–3mL) and can last 4–5 days.

Because pumps are FDA regulated in the United States, their design and

construction must be precisely documented and their performance must

meet strict guidelines. In addition, the hardware must provide comprehen-

sive self-test and fault reporting capabilities. This requires significant

amounts of additional circuitry not directly involved in the pump process,

as can be seen in Fig. 17 (Mossman, 2010).

To ensure they are truly portable, insulin pumps should not weigh more

than 100g and be no larger than a mobile phone, yet should only require