Page 233 - Handbook of Energy Engineering Calculations

P. 233

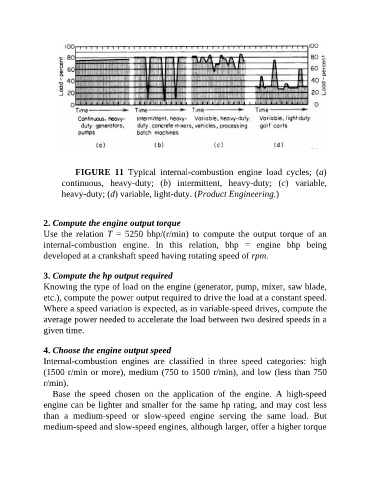

FIGURE 11 Typical internal-combustion engine load cycles; (a)

continuous, heavy-duty; (b) intermittent, heavy-duty; (c) variable,

heavy-duty; (d) variable, light-duty. (Product Engineering.)

2. Compute the engine output torque

Use the relation T = 5250 bhp/(r/min) to compute the output torque of an

internal-combustion engine. In this relation, bhp = engine bhp being

developed at a crankshaft speed having rotating speed of rpm.

3. Compute the hp output required

Knowing the type of load on the engine (generator, pump, mixer, saw blade,

etc.), compute the power output required to drive the load at a constant speed.

Where a speed variation is expected, as in variable-speed drives, compute the

average power needed to accelerate the load between two desired speeds in a

given time.

4. Choose the engine output speed

Internal-combustion engines are classified in three speed categories: high

(1500 r/min or more), medium (750 to 1500 r/min), and low (less than 750

r/min).

Base the speed chosen on the application of the engine. A high-speed

engine can be lighter and smaller for the same hp rating, and may cost less

than a medium-speed or slow-speed engine serving the same load. But

medium-speed and slow-speed engines, although larger, offer a higher torque