Page 289 - Handbook of Plastics Technologies

P. 289

ELASTOMERS

ELASTOMERS 4.81

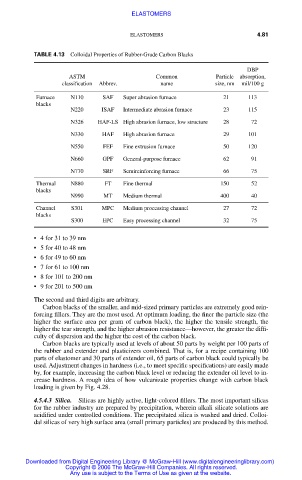

TABLE 4.13 Colloidal Properties of Rubber-Grade Carbon Blacks

DBP

ASTM Common Particle absorption,

classification Abbrev. name size, nm mil/100 g

Furnace N110 SAF Super abrasion furnace 21 113

blacks

N220 ISAF Intermediate abrasion furnace 23 115

N326 HAF-LS High abrasion furnace, low structure 28 72

N330 HAF High abrasion furnace 29 101

N550 FEF Fine extrusion furnace 50 120

N660 GPF General-purpose furnace 62 91

N770 SRF Semireinforcing furnace 66 75

Thermal N880 FT Fine thermal 150 52

blacks

N990 MT Medium thermal 400 40

Channel S301 MPC Medium processing channel 27 72

blacks

S300 EPC Easy processing channel 32 75

• 4 for 31 to 39 nm

• 5 for 40 to 48 nm

• 6 for 49 to 60 nm

• 7 for 61 to 100 nm

• 8 for 101 to 200 nm

• 9 for 201 to 500 nm

The second and third digits are arbitrary.

Carbon blacks of the smaller, and mid-sized primary particles are extremely good rein-

forcing fillers. They are the most used. At optimum loading, the finer the particle size (the

higher the surface area per gram of carbon black), the higher the tensile strength, the

higher the tear strength, and the higher abrasion resistance—however, the greater the diffi-

culty of dispersion and the higher the cost of the carbon black.

Carbon blacks are typically used at levels of about 50 parts by weight per 100 parts of

the rubber and extender and plasticizers combined. That is, for a recipe containing 100

parts of elastomer and 30 parts of extender oil, 65 parts of carbon black could typically be

used. Adjustment changes in hardness (i.e., to meet specific specifications) are easily made

by, for example, increasing the carbon black level or reducing the extender oil level to in-

crease hardness. A rough idea of how vulcanizate properties change with carbon black

loading is given by Fig. 4.28.

4.5.4.3 Silica. Silicas are highly active, light-colored fillers. The most important silicas

for the rubber industry are prepared by precipitation, wherein alkali silicate solutions are

acidified under controlled conditions. The precipitated silica is washed and dried. Colloi-

dal silicas of very high surface area (small primary particles) are produced by this method.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2006 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.