Page 325 - Handbook of Plastics Technologies

P. 325

PLASTICS ADDITIVES

PLASTICS ADDITIVES 5.5

butyl-p-cresol (TBC) or butylated hydroxy toluene (BHT). This is perfectly satisfactory in

polymers that can be processed at relatively low temperatures, such as LDPE. In higher-

temperature processing, it is too volatile and can be lost too rapidly to be useful. Then, we

resort to polyphenols of higher molecular weight and therefore lower volatility. Di- and

tetra-phenols are commonly used for such higher-temperature processing, giving much

better permanence (Tables 5.2 through 5.5).

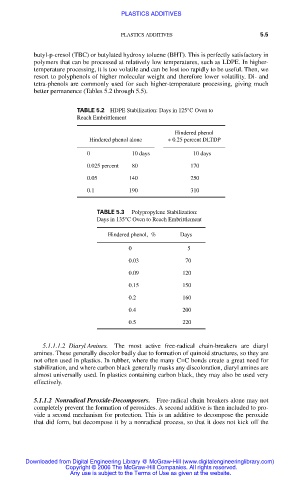

TABLE 5.2 HDPE Stabilization: Days in 125°C Oven to

Reach Embrittlement

Hindered phenol

Hindered phenol alone + 0.25 percent DLTDP

0 10 days 10 days

0.025 percent 80 170

0.05 140 250

0.1 190 310

TABLE 5.3 Polypropylene Stabilization:

Days in 135°C Oven to Reach Embrittlement

Hindered phenol, % Days

0 5

0.03 70

0.09 120

0.15 150

0.2 160

0.4 200

0.5 220

5.1.1.1.2 Diaryl Amines. The most active free-radical chain-breakers are diaryl

amines. These generally discolor badly due to formation of quinoid structures, so they are

not often used in plastics. In rubber, where the many C=C bonds create a great need for

stabilization, and where carbon black generally masks any discoloration, diaryl amines are

almost universally used. In plastics containing carbon black, they may also be used very

effectively.

5.1.1.2 Nonradical Peroxide-Decomposers. Free-radical chain breakers alone may not

completely prevent the formation of peroxides. A second additive is then included to pro-

vide a second mechanism for protection. This is an additive to decompose the peroxide

that did form, but decompose it by a nonradical process, so that it does not kick off the

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2006 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.