Page 332 - Handbook of Plastics Technologies

P. 332

PLASTICS ADDITIVES

5.12 CHAPTER 5

5.1.4.1 UV Reflectors. If a UV-resistant material will reflect UV light away from the

polymer, this can increase its lifetime tremendously. A metallized surface can give such

protection, and, if it is made extremely thin, it may be able to combine UV stability and

visible transparency. Pigmented fluoropolymer and acrylic coatings can be applied to the

polymer, either by coextrusion of capstock or by post-coating, and provide such stability.

More simply, dispersion of TiO and especially aluminum flake in the polymer can reflect

2

away most of the UV before it reaches more than a few surface molecules of the polymer,

and this technique has been very popular.

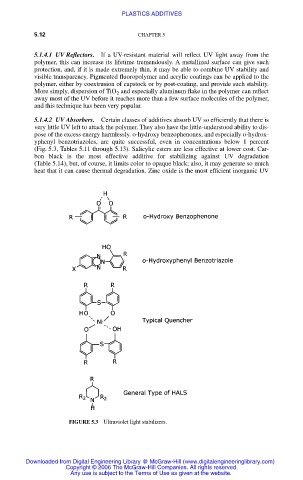

5.1.4.2 UV Absorbers. Certain classes of additives absorb UV so efficiently that there is

very little UV left to attack the polymer. They also have the little-understood ability to dis-

pose of the excess energy harmlessly. o-hydroxy benzophenones, and especially o-hydrox-

yphenyl benzotriazoles, are quite successful, even in concentrations below 1 percent

(Fig. 5.3, Tables 5.11 through 5.13). Salicylic esters are less effective at lower cost. Car-

bon black is the most effective additive for stabilizing against UV degradation

(Table 5.14), but, of course, it limits color to opaque black; also, it may generate so much

heat that it can cause thermal degradation. Zinc oxide is the most efficient inorganic UV

FIGURE 5.3 Ultraviolet light stabilizers.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2006 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.