Page 345 - Handbook of Plastics Technologies

P. 345

PLASTICS ADDITIVES

PLASTICS ADDITIVES 5.25

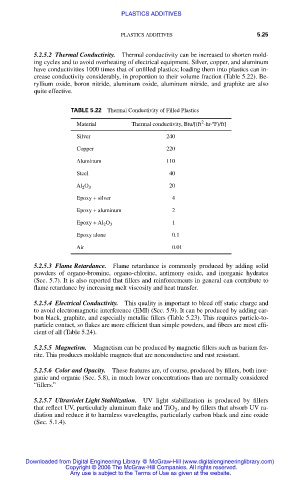

5.2.5.2 Thermal Conductivity. Thermal conductivity can be increased to shorten mold-

ing cycles and to avoid overheating of electrical equipment. Silver, copper, and aluminum

have conductivities 1000 times that of unfilled plastics; loading them into plastics can in-

crease conductivity considerably, in proportion to their volume fraction (Table 5.22). Be-

ryllium oxide, boron nitride, aluminum oxide, aluminum nitride, and graphite are also

quite effective.

TABLE 5.22 Thermal Conductivity of Filled Plastics

2

Material Thermal conductivity, Btu/[(ft -hr-ºF)/ft]

Silver 240

Copper 220

Aluminum 110

Steel 40

Al O 20

2 3

Epoxy + silver 4

Epoxy + aluminum 2

Epoxy + Al O 1

2 3

Epoxy alone 0.1

Air 0.01

5.2.5.3 Flame Retardance. Flame retardance is commonly produced by adding solid

powders of organo-bromine, organo-chlorine, antimony oxide, and inorganic hydrates

(Sec. 5.7). It is also reported that fillers and reinforcements in general can contribute to

flame retardance by increasing melt viscosity and heat transfer.

5.2.5.4 Electrical Conductivity. This quality is important to bleed off static charge and

to avoid electromagnetic interference (EMI) (Sec. 5.9). It can be produced by adding car-

bon black, graphite, and especially metallic fillers (Table 5.23). This requires particle-to-

particle contact, so flakes are more efficient than simple powders, and fibers are most effi-

cient of all (Table 5.24).

5.2.5.5 Magnetism. Magnetism can be produced by magnetic fillers such as barium fer-

rite. This produces moldable magnets that are nonconductive and rust resistant.

5.2.5.6 Color and Opacity. These features are, of course, produced by fillers, both inor-

ganic and organic (Sec. 5.8), in much lower concentrations than are normally considered

“fillers.”

5.2.5.7 Ultraviolet Light Stabilization. UV light stabilization is produced by fillers

that reflect UV, particularly aluminum flake and TiO , and by fillers that absorb UV ra-

2

diation and reduce it to harmless wavelengths, particularly carbon black and zinc oxide

(Sec. 5.1.4).

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2006 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.