Page 332 - Handbook of Properties of Textile and Technical Fibres

P. 332

Hemp, jute, banana, kenaf, ramie, sisal fibers 305

flexibility in the period of sowing and harvesting. The plantation requires 30e40 kg of

seed per hectare, sowing depth of 1e4 cm, and the best sowing time is when the soil is

2

at 15 C(Monti and Zatta, 2014). It is better to plant 60e80 plants/m while maintain-

ing the distance between the rows and distance within the rows of 25e35 cm, 2e5 cm,

respectively (Monti and Zatta, 2014; Akber Basri et al., 2014). Producers investigating

the production of a fiber crop should be able to estimate their harvest costs and obtain

production contracts that cover their entire cost of transportation to market.

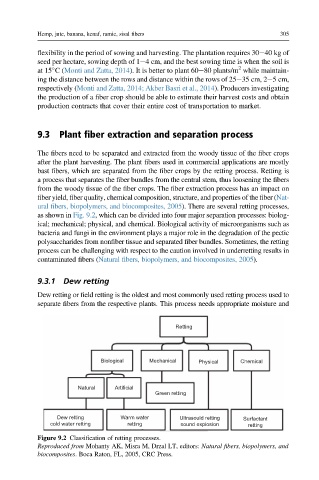

9.3 Plant fiber extraction and separation process

The fibers need to be separated and extracted from the woody tissue of the fiber crops

after the plant harvesting. The plant fibers used in commercial applications are mostly

bast fibers, which are separated from the fiber crops by the retting process. Retting is

a process that separates the fiber bundles from the central stem, thus loosening the fibers

from the woody tissue of the fiber crops. The fiber extraction process has an impact on

fiber yield, fiber quality, chemical composition, structure, and properties of the fiber (Nat-

ural fibers, biopolymers, and biocomposites, 2005). There are several retting processes,

as shown in Fig. 9.2, which can be divided into four major separation processes: biolog-

ical; mechanical; physical, and chemical. Biological activity of microorganisms such as

bacteria and fungi in the environment plays a major role in the degradation of the pectic

polysaccharides from nonfiber tissue and separated fiber bundles. Sometimes, the retting

process can be challenging with respect to the caution involved in underretting results in

contaminated fibers (Natural fibers, biopolymers, and biocomposites, 2005).

9.3.1 Dew retting

Dew retting or field retting is the oldest and most commonly used retting process used to

separate fibers from the respective plants. This process needs appropriate moisture and

Retting

Biological Mechanical Physical Chemical

Natural Artificial

Green retting

Dew retting Warm water Ultrasould retting Surfactant

cold water retting retting sound expiosion retting

Figure 9.2 Classification of retting processes.

Reproduced from Mohanty AK, Misra M, Drzal LT, editors: Natural fibers, biopolymers, and

biocomposites. Boca Raton, FL, 2005, CRC Press.