Page 63 - High Temperature Solid Oxide Fuel Cells Fundamentals, Design and Applications

P. 63

History 41

to construction of a working SOFC were the cathode material and the

electronically conducting interconnection material, together with the problems

of suitable fabrication techniques for producing gastight thin films of electrolyte

and interconnection, especially in their overlap regions [12 71.

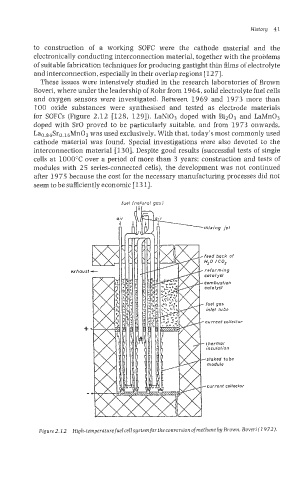

These issues were intensively studied in the research laboratories of Brown

Boveri, where under the leadership of Rohr from 1964, solid electrolyte fuel cells

and oxygen sensors were investigated. Between 1969 and 1973 more than

100 oxide substances were synthesised and tested as electrode materials

for SOFCs (Figure 2.12 [128, 1291). LaNi03 doped with Bi203 and LaR/ln03

doped with SrO proved to be particularly suitable, and from 1973 onwards,

Lao.s4Sro.16Mn03 was used exclusively. With that, today’s most commonly used

cathode material was found. Special investigations were also devoted to the

interconnection material [I 301. Despite good results (successful tests of single

cells at 1000°C over a period of more than 3 years: construction and tests of

modules with 2 5 series-connected cells), the development was not continued

after 19 75 because the cost for the necessary manufacturing processes did not

seem to be sufficiently economic [ 13 11.

fuel (nolural gas;

.*.

exhausl

+

Figure 2.22 High-temperaturefuelcelIsystenzfor the conversion ofmethane by Brown, Boveri (I 972).