Page 229 - How To Implement Lean Manufacturing

P. 229

Cellular Manufacturing 207

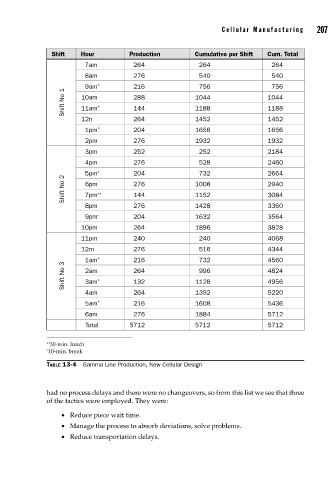

Shift Hour Production Cumulative per Shift Cum. Total

7am 264 264 264

8am 276 540 540

9am * 216 756 756

Shift No 1 10am * 288 1044 1044

1188

11am

144

1188

12n 264 1452 1452

1pm * 204 1656 1656

2pm 276 1932 1932

3pm 252 252 2184

4pm 276 528 2460

5pm ∗ 204 732 2664

Shift No 2 6pm ∗∗ 276 1008 2940

7pm

1152

144

3084

8pm 276 1428 3360

9pm ∗ 204 1632 3564

10pm 264 1896 3828

11pm 240 240 4068

12m 276 516 4344

1am * 216 732 4560

Shift No 3 2am * 264 1128 4824

996

4956

3am

132

4am 264 1392 5220

5am * 216 1608 5436

6am 276 1884 5712

Total 5712 5712 5712

∗∗ 30-min. lunch

∗ 10-min. break

TABLE 13-4 Gamma Line Production, New Cellular Design

had no process delays and there were no changeovers, so from this list we see that three

of the tactics were employed. They were:

• Reduce piece wait time.

• Manage the process to absorb deviations, solve problems.

• Reduce transportation delays.