Page 263 - Hydrocarbon

P. 263

250 Completion Technology and Intelligent Wells

wing valve (W)

swab valve

(SV)

Flowline

lower & upper

master valves christmas tree

(LMV,UMV)

tubing hanger

wellhead

control line for

safety valve casing

downhole safety valve (DHSV)

gauge cable

chemical

tubing

injection line

side pocket mandrel (SPM)

with gas lift valve (GLV)

permanent downhole gauge (PDHG)

chemical injection valve

polished bore receptacle (PBR)

production packer with seals (optional)

wireline entry guide (WEG)

gravel pack packer

formation isolation casing shoe

valve

sand control screens

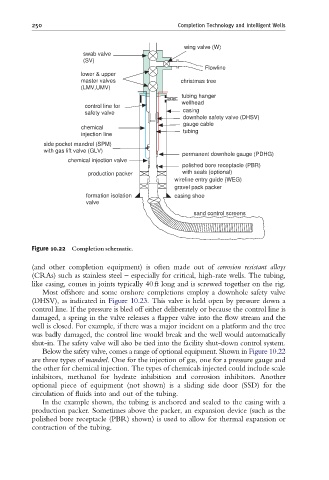

Figure 10.22 Completion schematic.

(and other completion equipment) is often made out of corrosion resistant alloys

(CRAs) such as stainless steel – especially for critical, high-rate wells. The tubing,

like casing, comes in joints typically 40 ft long and is screwed together on the rig.

Most offshore and some onshore completions employ a downhole safety valve

(DHSV), as indicated in Figure 10.23. This valve is held open by pressure down a

control line. If the pressure is bled off either deliberately or because the control line is

damaged, a spring in the valve releases a flapper valve into the flow stream and the

well is closed. For example, if there was a major incident on a platform and the tree

was badly damaged, the control line would break and the well would automatically

shut-in. The safety valve will also be tied into the facility shut-down control system.

Below the safety valve, comes a range of optional equipment. Shown in Figure 10.22

are three types of mandrel. One for the injection of gas, one for a pressure gauge and

the other for chemical injection. The types of chemicals injected could include scale

inhibitors, methanol for hydrate inhibition and corrosion inhibitors. Another

optional piece of equipment (not shown) is a sliding side door (SSD) for the

circulation of fluids into and out of the tubing.

In the example shown, the tubing is anchored and sealed to the casing with a

production packer. Sometimes above the packer, an expansion device (such as the

polished bore receptacle (PBR) shown) is used to allow for thermal expansion or

contraction of the tubing.