Page 66 - Hydrocarbon

P. 66

Drilling Engineering 53

crown block

drill pipes

platform

cable

travelling block

& hook

swivel head

kelly

vibrating screen rotary table

slush pump engines

mud ditch derrick floor

ground level

mud suction pit

blow-out

preventer

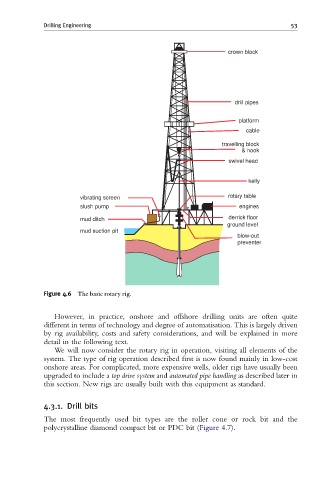

Figure 4.6 The basic rotary rig.

However, in practice, onshore and offshore drilling units are often quite

different in terms of technology and degree of automatisation. This is largely driven

by rig availability, costs and safety considerations, and will be explained in more

detail in the following text.

We will now consider the rotary rig in operation, visiting all elements of the

system. The type of rig operation described first is now found mainly in low-cost

onshore areas. For complicated, more expensive wells, older rigs have usually been

upgraded to include a top drive system and automated pipe handling as described later in

this section. New rigs are usually built with this equipment as standard.

4.3.1. Drill bits

The most frequently used bit types are the roller cone or rock bit and the

polycrystalline diamond compact bit or PDC bit (Figure 4.7).