Page 72 - Hydrocarbon

P. 72

Drilling Engineering 59

performance of OBM but are environmentally benign (e.g. synthetic oil-based mud

[SOBM]).

The choice of drilling fluid has a major impact on the evaluation and production

of a well. Later in this section, we will investigate the interaction between drilling

fluids, logging operations and the potential damage to well productivity caused by

mud invasion into the formation.

An important safety feature on every modern rig is the BOP. As discussed earlier

on, one of the purposes of the drilling mud is to provide a hydrostatic head of fluid

to counterbalance the pore pressure of fluids in permeable formations. However, for

a variety of reasons (see Section 4.7) the well may ‘kick’, that is formation fluids may

enter the wellbore, upsetting the balance of the system, pushing mud out of the

hole, and exposing the upper part of the hole and equipment to the higher pressures

of the deep subsurface. If left uncontrolled, this can lead to a blowout, a situation

where formation fluids flow to the surface in an uncontrolled manner.

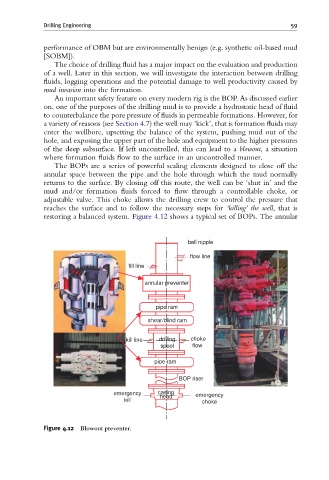

The BOPs are a series of powerful sealing elements designed to close off the

annular space between the pipe and the hole through which the mud normally

returns to the surface. By closing off this route, the well can be ‘shut in’ and the

mud and/or formation fluids forced to flow through a controllable choke, or

adjustable valve. This choke allows the drilling crew to control the pressure that

reaches the surface and to follow the necessary steps for ‘killing’ the well, that is

restoring a balanced system. Figure 4.12 shows a typical set of BOPs. The annular

bell nipple

flow line

fill line

annular preventer

pipe ram

shear/blind ram

kill line drilling choke

spool flow

pipe ram

BOP riser

emergency casing emergency

head

kill choke

Figure 4.12 Blowout preventer.