Page 87 - Hydrocarbon

P. 87

74 Casing and Cementing

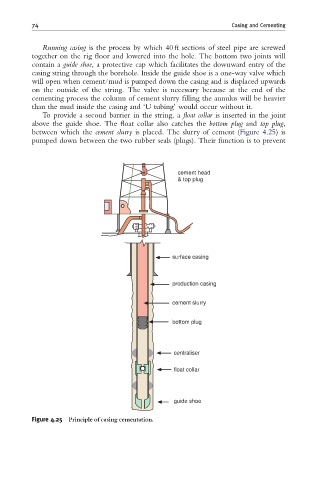

Running casing is the process by which 40 ft sections of steel pipe are screwed

together on the rig floor and lowered into the hole. The bottom two joints will

contain a guide shoe, a protective cap which facilitates the downward entry of the

casing string through the borehole. Inside the guide shoe is a one-way valve which

will open when cement/mud is pumped down the casing and is displaced upwards

on the outside of the string. The valve is necessary because at the end of the

cementing process the column of cement slurry filling the annulus will be heavier

than the mud inside the casing and ‘U tubing’ would occur without it.

To provide a second barrier in the string, a float collar is inserted in the joint

above the guide shoe. The float collar also catches the bottom plug and top plug,

between which the cement slurry is placed. The slurry of cement (Figure 4.25)is

pumped down between the two rubber seals (plugs). Their function is to prevent

cement head

& top plug

surface casing

production casing

cement slurry

bottom plug

centraliser

float collar

guide shoe

Figure 4.25 Principle of casing cementation.