Page 322 - Hydrocarbon Exploration and Production Second Edition

P. 322

Surface Facilities 309

Pipelines are cleaned and inspected using ‘pigs’. Pigs usually have a steel body

fitted with rubber cups and brushes or scrapers to remove wax and rust deposits

on the pipe wall, as the pig is pumped along the pipe. Sometimes spherical pigs

are sed for product separation or controlling liquid hold-up. In-field lines

handling untreated crude may have to be insulated to prevent wax formation

(Figure 11.41).

In recent years much more attention has been given to pipeline isolation, after

instances in which the contents of export pipelines fed platform fires, adding

significantly to damage and loss of life. Many export and in-field pipelines are now

fitted with emergency shutdown valves (ESDV) close to the production platform, to

isolate the pipeline in the event of an emergency.

11.2.5.2. Offshore loading

In areas where seabed relief makes pipelines vulnerable or where pipelines cannot be

justified on economic grounds, tankers are used to store and transport crude from

production centres. The simplest method for evacuation is to pump stabilised crude

from a processing facility directly to a tanker (Figure 11.42).

turntable

accommodation

ballast

pumps

fixed

ballast

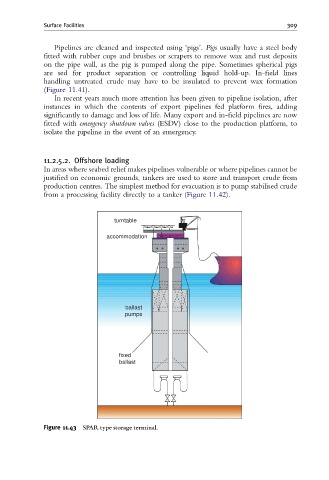

Figure 11.43 SPAR type storage terminal.