Page 71 - Hydrocarbon Exploration and Production Second Edition

P. 71

58 Drilling Systems and Equipment

desilter desander

mud

tanks

shale shaker

swivel

stand

pipe rotary

hose

kelly

drilling floor

mud pumps

BOP

stack

clean mud

casing

mud returns

drillpipe

annulus

bit

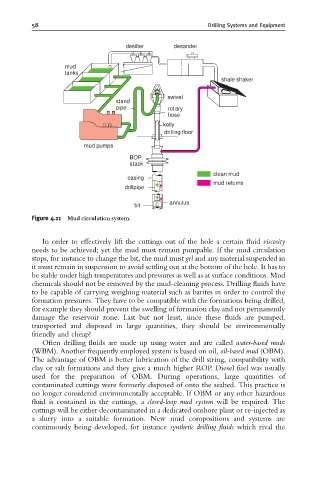

Figure 4.11 Mud circulation system.

In order to effectively lift the cuttings out of the hole a certain fluid viscosity

needs to be achieved; yet the mud must remain pumpable. If the mud circulation

stops, for instance to change the bit, the mud must gel and any material suspended in

it must remain in suspension to avoid settling out at the bottom of the hole. It has to

be stable under high temperatures and pressures as well as at surface conditions. Mud

chemicals should not be removed by the mud-cleaning process. Drilling fluids have

to be capable of carrying weighing material such as barites in order to control the

formation pressures. They have to be compatible with the formations being drilled,

for example they should prevent the swelling of formation clay and not permanently

damage the reservoir zone. Last but not least, since these fluids are pumped,

transported and disposed in large quantities, they should be environmentally

friendly and cheap!

Often drilling fluids are made up using water and are called water-based muds

(WBM). Another frequently employed system is based on oil, oil-based mud (OBM).

The advantage of OBM is better lubrication of the drill string, compatibility with

clay or salt formations and they give a much higher ROP. Diesel fuel was usually

used for the preparation of OBM. During operations, large quantities of

contaminated cuttings were formerly disposed of onto the seabed. This practice is

no longer considered environmentally acceptable. If OBM or any other hazardous

fluid is contained in the cuttings, a closed-loop mud system will be required. The

cuttings will be either decontaminated in a dedicated onshore plant or re-injected as

a slurry into a suitable formation. New mud compositions and systems are

continuously being developed, for instance synthetic drilling fluids which rival the