Page 34 - Improving Machinery Reliability

P. 34

Requirements Specificatiori 7

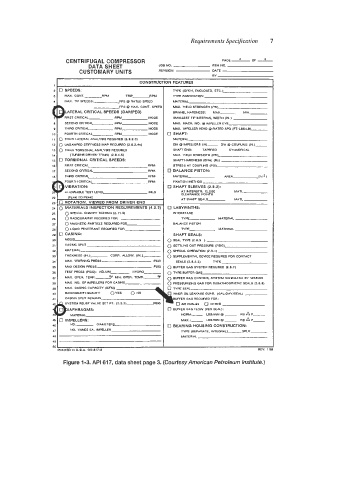

CENTRIFUGAL COMPRESSOR P A G E 3 OF b

DATA SHEET JOB NO. ITEM NO.

REVlSlON

CUSTOMARY UNITS CONSTRUCTION FEATURES DATE

I * RPM FPS TRIP RPM TYPE (OPEN. ENCLOSED, ETC.)

1

2 0 SPEEDS:

TYPE FABRICATION

MAX. CONT.

3

4

MATERIAL

RATE0 SPEED

MAX np SPEEDS:

MAX. YIELD STRENGTH (PSI)

FPS a MAX CONT. SPEEC

TERAL CRITICAL SPEEDS (DAMPED)

SMALLEST TIP INTERNAL WIDTH (IN, 1

FIRST CRITICAL

SECOND CRITICAL, RPM MODE BRINNEL HARDNESS: MAX- MIN.

MODE

MAX. MACH. NO. a IMPELLER EVE

RPM

e THIRD cRincAL RPM MODE MAX. IMPELLER HEAD a RATED sm (FT-LBsILB)-

10 FOURTH CRITICAL RPM MODE 0 SHAFT:

11 0 TRAIN LATERAL ANALYSIS REQUIRED (2.0.2.3) MATERIAL

12 0 UNOAMPEO STIFFNESS MAP REOUIREO (2.8.2.401 OIA @ IMPELLERS (IN)- OIA a COUPLING (IN.)-

13 0 TRAIN TORSIONAL ANALYSIS REQUIRED SHAFT END: TAPERED CYLINDRICAL

I4 (WRBINE ORNEN TRAIN) 12.0.4.6) MAX. YIELD STRENGTH (PSI)

15 0 TORSIONAL CRITICAL SPEEDS: SHAFT HARDNESS IBNH) (Re)

16 FIRST cRincAL RPM STRESS AT COURING (PSI)

17 SECOND CRITICAL RPM 0 BALANCE PISTON:

16 THlRO CRITICN RPM MATERIAL AREA (IN !

FOURTH CRITICAL RPM FIXATION METHOD

)VIBRATION: 0 SHAFT SLEEVES (2.8.2):

! ALLOWABLE TEST LEVEL. MILS AT INTERSTG. CLOSE MATL

CLEARANCE POINTS

(PEAK TO PEAK1 ATSHAFT SEALS MATL

23 0 ROTATION, VIEWED FROM DRIVEN END

24 0 MATERIALS INSPECTION REQUIREMENTS (4.2.3) 0 LABYRINTHS:

21 0 SPECIAL CHARPV TESTING 12.11.3) INTERSTAGE

2( 0 RADIOGRNWY REQUIRED FOR TYPE MATERIAL

21 0 MAGNETIC PARTICLE REOUIRED FOR BALANCE FiSTON

21 0 LIQUID PENETRANT REQUIRED FOR TYPE MATERIAL

2( 0 CASING: SHAFT SEALS:

3( MODEL 0 SEAL TYPE (2.8.3

31 CASING Sfti7 0 SETTLING OUT PRESSURE (PSIGJ

3; MATERIAL 0 SPECIAL OPERATtON (2.8.1)

3: THICKNESS (IN.) CORR. ALLOW. (IN.) 0 SUPREMENTAL DEVICE REOUIREO FOR CONTACT

3r MAX. WORIUNG PRESS PSlG SEALS (2.8.3.2) TYPE

3! MAX DESIGN PRESS PSI0 0 BUFFER GAS SYSTEM REQUIREO (2.8.71

24 TEST PRESS (PSIG): HELIUM HYDRO 0 TYPE BUFFER GAS

3i MAX. OPER. TEMP.OF MIN. OPER. TEMP.* 0 BUFFER QAS CONTROL SYSTEM SCHEMATIC BY VENDOR

31 MAX NO. OF IMPELLERS FOR CASING 0 PRESSURIZING GAS FOR SUBATMOSPHERIC SEALS 12.8.61

31 Mu(. CASING CAPACITY (ICFM) 0 TYPE SEAL

41 RADIOGRAPH QUALrTy 0 YES 0 NO ‘I 0 INNER OIL LEAKAGE GUAR. (GALfDAY/SEAL)

4 CASING SRlT SEALING )PBUFFER GAS REQUIRED FOR:

4; STEM RELIEF VALVE SET PT. (2.2.3) PSlG 0 AIR RUN-IN 0 OTHER

4 IAPHRAQMS: 0 BUFFER GAS FLOW (PER SEAL):

A

PSI

MATERIAL NORM:- LBSIMIN @ - P-

4! 0 IMPELLERS: MU(.:- LBSlMlN a __ PSI A P-

41 NO. DIAMETERS O BEARINQ HOUSINQ CONSTRUCTION:

4 NO, VANES EA. IMPELLER TYPE (SEPARATE. 1NTEGRAL)~SUlT

4 MATERIAL

I_

PAINTED IN U.S.A. DS-617-3 REV. 1.

Figure 1-3. API 617, data sheet page 3. (Courtesy American Petroleum Institute.)