Page 6 - Industrial Cutting of Textile Materials

P. 6

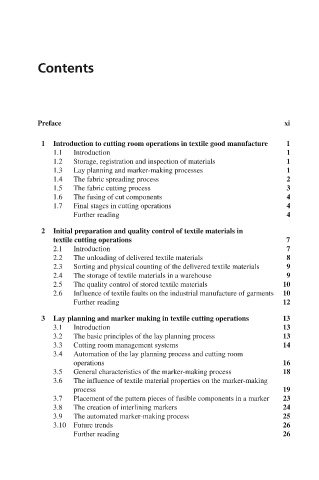

Contents

Preface xi

1 Introduction to cutting room operations in textile good manufacture 1

1.1 Introduction 1

1.2 Storage, registration and inspection of materials 1

1.3 Lay planning and marker-making processes 1

1.4 The fabric spreading process 2

1.5 The fabric cutting process 3

1.6 The fusing of cut components 4

1.7 Final stages in cutting operations 4

Further reading 4

2 Initial preparation and quality control of textile materials in

textile cutting operations 7

2.1 Introduction 7

2.2 The unloading of delivered textile materials 8

2.3 Sorting and physical counting of the delivered textile materials 9

2.4 The storage of textile materials in a warehouse 9

2.5 The quality control of stored textile materials 10

2.6 Influence of textile faults on the industrial manufacture of garments 10

Further reading 12

3 Lay planning and marker making in textile cutting operations 13

3.1 Introduction 13

3.2 The basic principles of the lay planning process 13

3.3 Cutting room management systems 14

3.4 Automation of the lay planning process and cutting room

operations 16

3.5 General characteristics of the marker-making process 18

3.6 The influence of textile material properties on the marker-making

process 19

3.7 Placement of the pattern pieces of fusible components in a marker 23

3.8 The creation of interlining markers 24

3.9 The automated marker-making process 25

3.10 Future trends 26

Further reading 26