Page 68 - Industrial Cutting of Textile Materials

P. 68

Manual spreading of textile materials 55

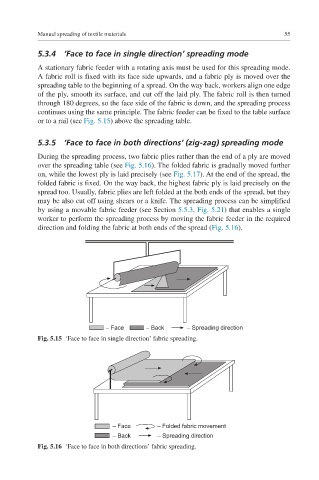

5.3.4 ‘Face to face in single direction’ spreading mode

A stationary fabric feeder with a rotating axis must be used for this spreading mode.

A fabric roll is fixed with its face side upwards, and a fabric ply is moved over the

spreading table to the beginning of a spread. On the way back, workers align one edge

of the ply, smooth its surface, and cut off the laid ply. The fabric roll is then turned

through 180 degrees, so the face side of the fabric is down, and the spreading process

continues using the same principle. The fabric feeder can be fixed to the table surface

or to a rail (see Fig. 5.15) above the spreading table.

5.3.5 ‘Face to face in both directions’ (zig-zag) spreading mode

During the spreading process, two fabric plies rather than the end of a ply are moved

over the spreading table (see Fig. 5.16). The folded fabric is gradually moved further

on, while the lowest ply is laid precisely (see Fig. 5.17). At the end of the spread, the

folded fabric is fixed. On the way back, the highest fabric ply is laid precisely on the

spread too. Usually, fabric plies are left folded at the both ends of the spread, but they

may be also cut off using shears or a knife. The spreading process can be simplified

by using a movable fabric feeder (see Section 5.5.3, Fig. 5.21) that enables a single

worker to perform the spreading process by moving the fabric feeder in the required

direction and folding the fabric at both ends of the spread (Fig. 5.16).

– Face – Back – Spreading direction

Fig. 5.15 ‘Face to face in single direction’ fabric spreading.

– Face – Folded fabric movement

– Back – Spreading direction

Fig. 5.16 ‘Face to face in both directions’ fabric spreading.