Page 145 - Injection Molding Advanced Troubleshooting Guide

P. 145

132 15 Black or Brown Specks

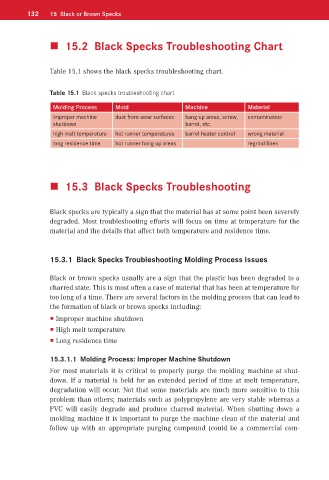

15.2 Black Specks Troubleshooting Chart

Table 15.1 shows the black specks troubleshooting chart.

Table 15.1 Black specks troubleshooting chart

Molding Process Mold Machine Material

improper machine dust from wear surfaces hang up areas, screw, contamination

shutdown barrel, etc.

high melt temperature hot runner temperatures barrel heater control wrong material

long residence time hot runner hang up areas regrind fines

15.3 Black Specks Troubleshooting

Black specks are typically a sign that the material has at some point been severely

degraded. Most troubleshooting efforts will focus on time at temperature for the

material and the details that affect both temperature and residence time.

15.3.1 Black Specks Troubleshooting Molding Process Issues

Black or brown specks usually are a sign that the plastic has been degraded to a

charred state. This is most often a case of material that has been at temperature for

too long of a time. There are several factors in the molding process that can lead to

the formation of black or brown specks including:

Improper machine shutdown

High melt temperature

Long residence time

15.3.1.1 Molding Process: Improper Machine Shutdown

For most materials it is critical to properly purge the molding machine at shut-

down. If a material is held for an extended period of time at melt temperature,

degradation will occur. Not that some materials are much more sensitive to this

problem than others; materials such as polypropylene are very stable whereas a

PVC will easily degrade and produce charred material. When shutting down a

molding machine it is important to purge the machine clean of the material and

follow up with an appropriate purging compound (could be a commercial com-