Page 184 - Injection Molding Advanced Troubleshooting Guide

P. 184

174 19 Buildup

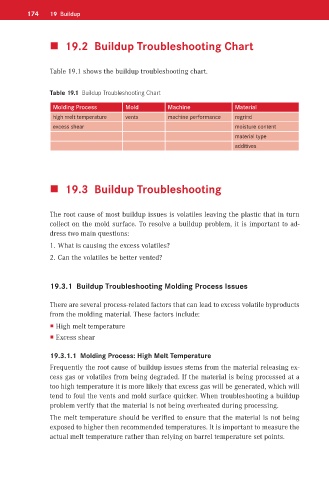

19.2 Buildup Troubleshooting Chart

Table 19.1 shows the buildup troubleshooting chart.

Table 19.1 Buildup Troubleshooting Chart

Molding Process Mold Machine Material

high melt temperature vents machine performance regrind

excess shear moisture content

material type

additives

19.3 Buildup Troubleshooting

The root cause of most buildup issues is volatiles leaving the plastic that in turn

collect on the mold surface. To resolve a buildup problem, it is important to ad-

dress two main questions:

1. What is causing the excess volatiles?

2. Can the volatiles be better vented?

19.3.1 Buildup Troubleshooting Molding Process Issues

There are several process-related factors that can lead to excess volatile byproducts

from the molding material. These factors include:

High melt temperature

Excess shear

19.3.1.1 Molding Process: High Melt Temperature

Frequently the root cause of buildup issues stems from the material releasing ex-

cess gas or volatiles from being degraded. If the material is being processed at a

too high temperature it is more likely that excess gas will be generated, which will

tend to foul the vents and mold surface quicker. When troubleshooting a buildup

problem verify that the material is not being overheated during processing.

The melt temperature should be verified to ensure that the material is not being

exposed to higher then recommended temperatures. It is important to measure the

actual melt temperature rather than relying on barrel temperature set points.