Page 209 - Injection Molding Advanced Troubleshooting Guide

P. 209

200 22 Color Swirls

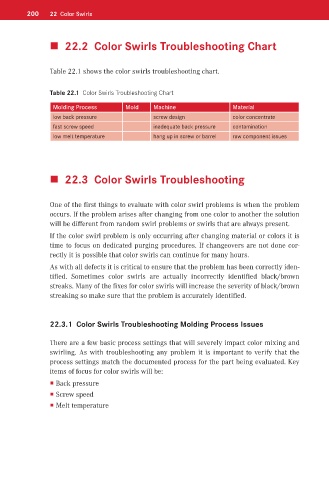

22.2 Color Swirls Troubleshooting Chart

Table 22.1 shows the color swirls troubleshooting chart.

Table 22.1 Color Swirls Troubleshooting Chart

Molding Process Mold Machine Material

low back pressure screw design color concentrate

fast screw speed inadequate back pressure contamination

low melt temperature hang up in screw or barrel raw component issues

22.3 Color Swirls Troubleshooting

One of the first things to evaluate with color swirl problems is when the problem

occurs. If the problem arises after changing from one color to another the solution

will be different from random swirl problems or swirls that are always present.

If the color swirl problem is only occurring after changing material or colors it is

time to focus on dedicated purging procedures. If changeovers are not done cor-

rectly it is possible that color swirls can continue for many hours.

As with all defects it is critical to ensure that the problem has been correctly iden-

tified. Sometimes color swirls are actually incorrectly identified black/brown

streaks. Many of the fixes for color swirls will increase the severity of black/brown

streaking so make sure that the problem is accurately identified.

22.3.1 Color Swirls Troubleshooting Molding Process Issues

There are a few basic process settings that will severely impact color mixing and

swirling. As with troubleshooting any problem it is important to verify that the

process settings match the documented process for the part being evaluated. Key

items of focus for color swirls will be:

Back pressure

Screw speed

Melt temperature