Page 233 - Injection Molding Advanced Troubleshooting Guide

P. 233

224 24 Cracking

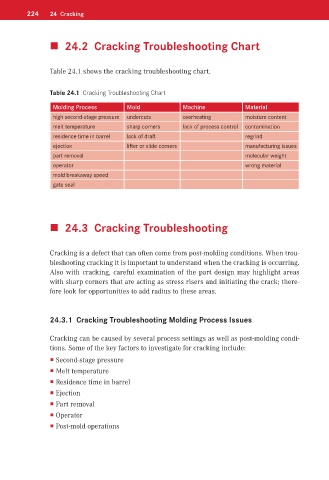

24.2 Cracking Troubleshooting Chart

Table 24.1 shows the cracking troubleshooting chart.

Table 24.1 Cracking Troubleshooting Chart

Molding Process Mold Machine Material

high second-stage pressure undercuts overheating moisture content

melt temperature sharp corners lack of process control contamination

residence time in barrel lack of draft regrind

ejection lifter or slide corners manufacturing issues

part removal molecular weight

operator wrong material

mold breakaway speed

gate seal

24.3 Cracking Troubleshooting

Cracking is a defect that can often come from post-molding conditions. When trou-

bleshooting cracking it is important to understand when the cracking is occurring.

Also with cracking, careful examination of the part design may highlight areas

with sharp corners that are acting as stress risers and initiating the crack; there-

fore look for opportunities to add radius to these areas.

24.3.1 Cracking Troubleshooting Molding Process Issues

Cracking can be caused by several process settings as well as post-molding condi-

tions. Some of the key factors to investigate for cracking include:

Second-stage pressure

Melt temperature

Residence time in barrel

Ejection

Part removal

Operator

Post-mold operations