Page 350 - Injection Molding Advanced Troubleshooting Guide

P. 350

346 36 Part Sticking on Ejector

36.2 Part Sticking on Ejector Trouble-

shooting Chart

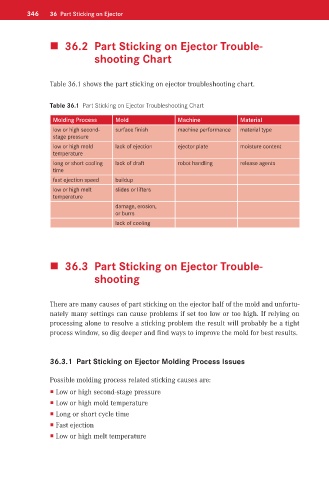

Table 36.1 shows the part sticking on ejector troubleshooting chart.

Table 36.1 Part Sticking on Ejector Troubleshooting Chart

Molding Process Mold Machine Material

low or high second- surface finish machine performance material type

stage pressure

low or high mold lack of ejection ejector plate moisture content

temperature

long or short cooling lack of draft robot handling release agents

time

fast ejection speed buildup

low or high melt slides or lifters

temperature

damage, erosion,

or burrs

lack of cooling

36.3 Part Sticking on Ejector Trouble-

shooting

There are many causes of part sticking on the ejector half of the mold and unfortu-

nately many settings can cause problems if set too low or too high. If relying on

processing alone to resolve a sticking problem the result will probably be a tight

process window, so dig deeper and find ways to improve the mold for best results.

36.3.1 Part Sticking on Ejector Molding Process Issues

Possible molding process related sticking causes are:

Low or high second-stage pressure

Low or high mold temperature

Long or short cycle time

Fast ejection

Low or high melt temperature