Page 391 - Injection Molding Advanced Troubleshooting Guide

P. 391

40.3 Short Shot Troubleshooting 389

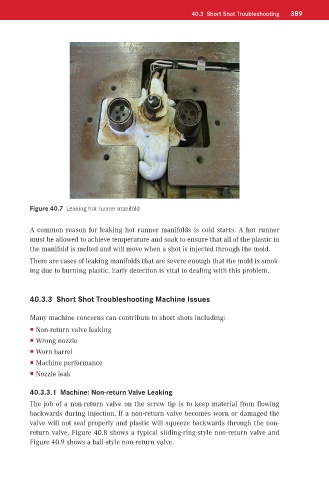

Figure 40.7 Leaking hot runner manifold

A common reason for leaking hot runner manifolds is cold starts. A hot runner

must be allowed to achieve temperature and soak to ensure that all of the plastic in

the manifold is melted and will move when a shot is injected through the mold.

There are cases of leaking manifolds that are severe enough that the mold is smok-

ing due to burning plastic. Early detection is vital to dealing with this problem.

40.3.3 Short Shot Troubleshooting Machine Issues

Many machine concerns can contribute to short shots including:

Non-return valve leaking

Wrong nozzle

Worn barrel

Machine performance

Nozzle leak

40.3.3.1 Machine: Non-return Valve Leaking

The job of a non-return valve on the screw tip is to keep material from flowing

backwards during injection. If a non-return valve becomes worn or damaged the

valve will not seal properly and plastic will squeeze backwards through the non-

return valve. Figure 40.8 shows a typical sliding-ring-style non-return valve and

Figure 40.9 shows a ball-style non-return valve.