Page 54 - Injection Molding Advanced Troubleshooting Guide

P. 54

4.2 Gate Size, Shape, and Taper 37

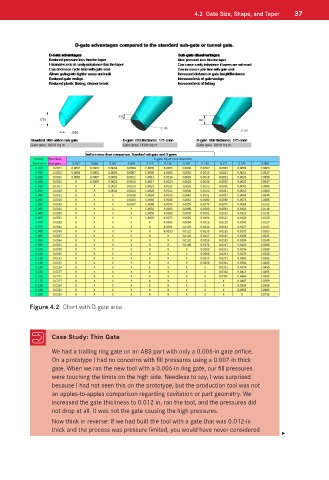

Figure 4.2 Chart with D-gate area

Case Study: Thin Gate

We had a trailing ring gate on an ABS part with only a 0.006-in gate orifice.

On a prototype I had no concerns with fill pressures using a 0.007-in thick

gate. When we ran the new tool with a 0.006-in ring gate, our fill pressures

were touching the limits on the high side. Needless to say, I was surprised

because I had not seen this on the prototype, but the production tool was not

an apples-to-apples comparison regarding cavitation or part geometry. We

increased the gate thickness to 0.012 in, ran the tool, and the pressures did

not drop at all. It was not the gate causing the high pressures.

Now think in reverse: If we had built the tool with a gate that was 0.012-in

thick and the process was pressure limited, you would have never considered

▸