Page 103 -

P. 103

Organizational Data 85

specifi c types of materials (e.g., semifi nished goods). More specifi c storage

locations include shelves, bins, cabinets, and trays. Locations range from small

bins to entire buildings, depending on the size of the materials being stored.

For example, the storage location for nuts and bolts will be a small container,

whereas the storage location for an aircraft will be a hanger. Organizations

with sophisticated inventory management systems can manage their materials

on a more detailed level. We address these systems in the chapter on inventory

and warehouse management.

Regardless of the nature of the enterprise, however, a plant must have at

least one storage location if it needs to track the quantity and value of materi-

als in its inventory. For example, a plant that serves as a production or storage

facility must maintain accurate records of the quantity and value of raw mate-

rials, semifi nished goods, and fi nished goods. The plant cannot perform this

function without storage locations. In other cases, however, this function is not

necessary. For example, an enterprise does not typically track the quantity or

value of supplies it purchases for a corporate offi ce (a plant). Therefore, a stor-

age location is not essential. Signifi cantly, although one plant can have multiple

storage locations, each storage location can belong to only one plant.

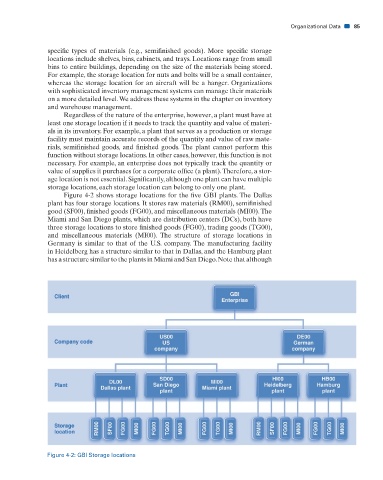

Figure 4-2 shows storage locations for the fi ve GBI plants. The Dallas

plant has four storage locations. It stores raw materials (RM00), semifi nished

good (SF00), fi nished goods (FG00), and miscellaneous materials (MI00). The

Miami and San Diego plants, which are distribution centers (DCs), both have

three storage locations to store fi nished goods (FG00), trading goods (TG00),

and miscellaneous materials (MI00). The structure of storage locations in

Germany is similar to that of the U.S. company. The manufacturing facility

in Heidelberg has a structure similar to that in Dallas, and the Hamburg plant

has a structure similar to the plants in Miami and San Diego. Note that although

Figure 4-2: GBI Storage locations

31/01/11 7:35 PM

CH004.indd 85 31/01/11 7:35 PM

CH004.indd 85