Page 246 -

P. 246

228 CHAPTER 7 Inventory and Warehouse Management Processes

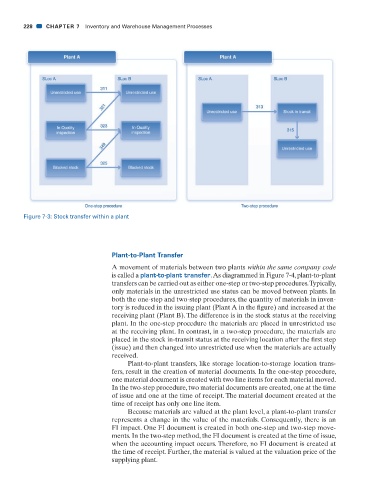

Figure 7-3: Stock transfer within a plant

Plant-to-Plant Transfer

A movement of materials between two plants within the same company code

is called a plant-to-plant transfer. As diagrammed in Figure 7-4, plant-to-plant

transfers can be carried out as either one-step or two-step procedures. Typically,

only materials in the unrestricted use status can be moved between plants. In

both the one-step and two-step procedures, the quantity of materials in inven-

tory is reduced in the issuing plant (Plant A in the fi gure) and increased at the

receiving plant (Plant B). The difference is in the stock status at the receiving

plant. In the one-step procedure the materials are placed in unrestricted use

at the receiving plant. In contrast, in a two-step procedure, the materials are

placed in the stock in-transit status at the receiving location after the fi rst step

(issue) and then changed into unrestricted use when the materials are actually

received.

Plant-to-plant transfers, like storage location-to-storage location trans-

fers, result in the creation of material documents. In the one-step procedure,

one material document is created with two line items for each material moved.

In the two-step procedure, two material documents are created, one at the time

of issue and one at the time of receipt. The material document created at the

time of receipt has only one line item.

Because materials are valued at the plant level, a plant-to-plant transfer

represents a change in the value of the materials. Consequently, there is an

FI impact. One FI document is created in both one-step and two-step move-

ments. In the two-step method, the FI document is created at the time of issue,

when the accounting impact occurs. Therefore, no FI document is created at

the time of receipt. Further, the material is valued at the valuation price of the

supplying plant.

31/01/11 6:41 AM

CH007.indd 228

CH007.indd 228 31/01/11 6:41 AM