Page 98 - Intelligent Digital Oil And Gas Fields

P. 98

Instrumentation and Measurement 67

robust and stable devices, which are now easily programmed as discussed

above (see Section 2.2.4).

2.3.3 SCADA and Distributed Control System

Most modern production platforms and FPSOs use distributed control sys-

tems (DCS). Most modern unconventional assets are installing simpler

SCADA systems. Many assets are using a generic SCADA system, such as

those applied in other industries (e.g., manufacturing). Others are electing

to deploy a domain-specific SCADA/control platform—especially on arti-

ficial lift wells—or even two systems to meet their needs.

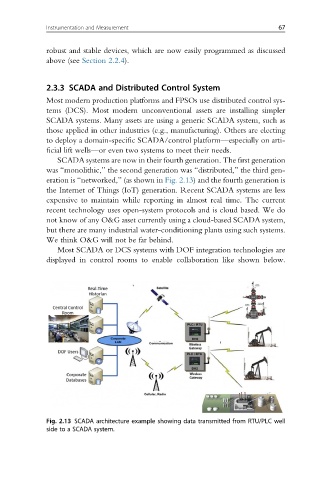

SCADA systems are now in their fourth generation. The first generation

was “monolithic,” the second generation was “distributed,” the third gen-

eration is “networked,” (as shown in Fig. 2.13) and the fourth generation is

the Internet of Things (IoT) generation. Recent SCADA systems are less

expensive to maintain while reporting in almost real time. The current

recent technology uses open-system protocols and is cloud based. We do

not know of any O&G asset currently using a cloud-based SCADA system,

but there are many industrial water-conditioning plants using such systems.

We think O&G will not be far behind.

Most SCADA or DCS systems with DOF integration technologies are

displayed in control rooms to enable collaboration like shown below.

Fig. 2.13 SCADA architecture example showing data transmitted from RTU/PLC well

side to a SCADA system.