Page 271 - Intro Predictive Maintenance

P. 271

262 An Introduction to Predictive Maintenance

Figure 12–1 “Go/no-go” standards.

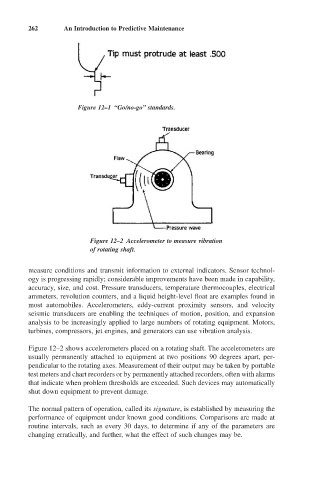

Figure 12–2 Accelerometer to measure vibration

of rotating shaft.

measure conditions and transmit information to external indicators. Sensor technol-

ogy is progressing rapidly; considerable improvements have been made in capability,

accuracy, size, and cost. Pressure transducers, temperature thermocouples, electrical

ammeters, revolution counters, and a liquid height-level float are examples found in

most automobiles. Accelerometers, eddy-current proximity sensors, and velocity

seismic transducers are enabling the techniques of motion, position, and expansion

analysis to be increasingly applied to large numbers of rotating equipment. Motors,

turbines, compressors, jet engines, and generators can use vibration analysis.

Figure 12–2 shows accelerometers placed on a rotating shaft. The accelerometers are

usually permanently attached to equipment at two positions 90 degrees apart, per-

pendicular to the rotating axes. Measurement of their output may be taken by portable

test meters and chart recorders or by permanently attached recorders, often with alarms

that indicate when problem thresholds are exceeded. Such devices may automatically

shut down equipment to prevent damage.

The normal pattern of operation, called its signature, is established by measuring the

performance of equipment under known good conditions. Comparisons are made at

routine intervals, such as every 30 days, to determine if any of the parameters are

changing erratically, and further, what the effect of such changes may be.