Page 400 - Intro Predictive Maintenance

P. 400

Maintaining the Program 391

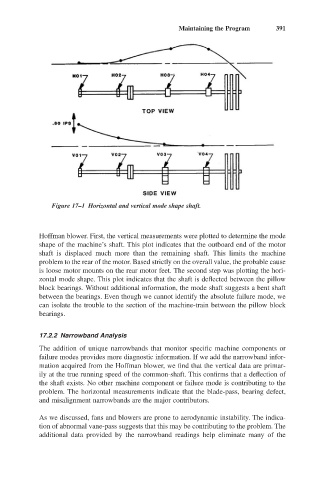

Figure 17–1 Horizontal and vertical mode shape shaft.

Hoffman blower. First, the vertical measurements were plotted to determine the mode

shape of the machine’s shaft. This plot indicates that the outboard end of the motor

shaft is displaced much more than the remaining shaft. This limits the machine

problem to the rear of the motor. Based strictly on the overall value, the probable cause

is loose motor mounts on the rear motor feet. The second step was plotting the hori-

zontal mode shape. This plot indicates that the shaft is deflected between the pillow

block bearings. Without additional information, the mode shaft suggests a bent shaft

between the bearings. Even though we cannot identify the absolute failure mode, we

can isolate the trouble to the section of the machine-train between the pillow block

bearings.

17.2.2 Narrowband Analysis

The addition of unique narrowbands that monitor specific machine components or

failure modes provides more diagnostic information. If we add the narrowband infor-

mation acquired from the Hoffman blower, we find that the vertical data are primar-

ily at the true running speed of the common-shaft. This confirms that a deflection of

the shaft exists. No other machine component or failure mode is contributing to the

problem. The horizontal measurements indicate that the blade-pass, bearing defect,

and misalignment narrowbands are the major contributors.

As we discussed, fans and blowers are prone to aerodynamic instability. The indica-

tion of abnormal vane-pass suggests that this may be contributing to the problem. The

additional data provided by the narrowband readings help eliminate many of the