Page 162 - Introduction to Marine Engineering

P. 162

148 Auxiliaries

SOIL

VENT IMLfT

o

HUM AN BOD V

WASTE FROM

WeVAHO

URIMAL3

CONTROL PANE U

MAWCi ni»»f CHLORINE AERATION SETTLING AERATION

CONTACT

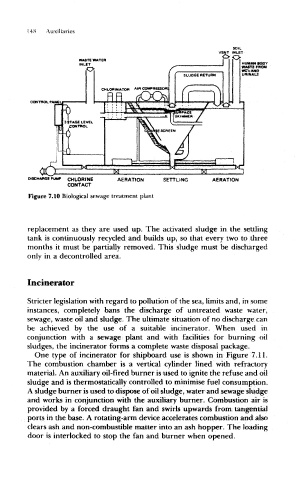

Figure 7.10 Biological sewage treatment plant

replacement as they are used up. The activated sludge in the settling

tank is continuously recycled and builds up, so that every two to three

months it must be partially removed. This sludge must be discharged

only in a decontrolled area.

Incinerator

Stricter legislation with regard to pollution of the sea, limits and, in some

instances, completely bans the discharge of untreated waste water,

sewage, waste oil and sludge. The ultimate situation of no discharge can

be achieved by the use of a suitable incinerator. When used in

conjunction with a sewage plant and with facilities for burning oil

sludges, the incinerator forms a complete waste disposal package.

One type of incinerator for shipboard use is shown in Figure 7.11.

The combustion chamber is a vertical cylinder lined with refractory

material. An auxiliary oil-fired burner is used to ignite the refuse and oil

sludge and is thermostatically controlled to minimise fuel consumption.

A sludge burner is used to dispose of oil sludge, water and sewage sludge

and works in conjunction with the auxiliary burner. Combustion air is

provided by a forced draught fan and swirls upwards from tangential

ports in the base. A rotating-arm device accelerates combustion and also

clears ash and non-combustible matter into an ash hopper. The loading

door is interlocked to stop the fan and burner when opened.