Page 175 - Introduction to Marine Engineering

P. 175

Fuel oils, lubricating oils and their treatment 161

positioned as shown in the central tube. A spring-loaded bypass is shown

in the diagram, for lubricating oil filters only, to ensure a flow of oil

should the filter become blocked. The cartridge in the design shown is

disposable although designs exist to enable back-flushing with com-

pressed air to clean the filter element as required. The filter unit shown will

be one of a pair which can be alternately in service.

In full-flow filtration systems all the oil passes through the filter on its

way to the engine. In a by-pass system most of the oil goes to the

lubrication system and a part is by-passed to a filter. A higher pressure

drop across the filter can then be used and a slower filtration rate. A

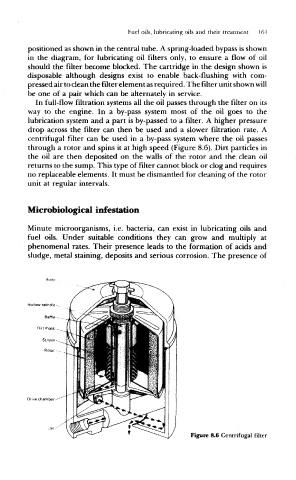

centrifugal filter can be used in a by-pass system where the oil passes

through a rotor and spins it at high speed (Figure 8.6). Dirt particles in

the oil are then deposited on the walls of the rotor and the clean oil

returns to the sump. This type of filter cannot block or clog and requires

no replaceable elements. It must be dismantled for cleaning of the rotor

unit at regular intervals.

Microbiological infestation

Minute microorganisms, i.e. bacteria, can exist in lubricating oils and

fuel oils. Under suitable conditions they can grow and multiply at

phenomenal rates. Their presence leads to the formation of acids and

sludge, metal staining, deposits and serious corrosion. The presence of

Figure 8.6 Centrifugai filter