Page 96 - Materials Chemistry, Second Edition

P. 96

82 A.-S. Nizami and I. M. Ismail

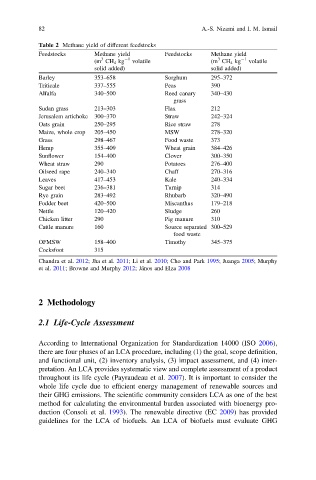

Table 2 Methane yield of different feedstocks

Feedstocks Methane yield Feedstocks Methane yield

3

3

(m CH 4 kg -1 volatile (m CH 4 kg -1 volatile

solid added) solid added)

Barley 353–658 Sorghum 295–372

Triticale 337–555 Peas 390

Alfalfa 340–500 Reed canary 340–430

grass

Sudan grass 213–303 Flax 212

Jerusalem artichoke 300–370 Straw 242–324

Oats grain 250–295 Rice straw 278

Maize, whole crop 205–450 MSW 278–320

Grass 298–467 Food waste 373

Hemp 355–409 Wheat grain 384–426

Sunflower 154–400 Clover 300–350

Wheat straw 290 Potatoes 276–400

Oilseed rape 240–340 Chaff 270–316

Leaves 417–453 Kale 240–334

Sugar beet 236–381 Turnip 314

Rye grain 283–492 Rhubarb 320–490

Fodder beet 420–500 Miscanthus 179–218

Nettle 120–420 Sludge 260

Chicken litter 290 Pig manure 310

Cattle manure 160 Source separated 300–529

food waste

OFMSW 158–400 Timothy 345–375

Cocksfoot 315

Chandra et al. 2012; Jha et al. 2011; Li et al. 2010; Cho and Park 1995; Juanga 2005; Murphy

et al. 2011; Browne and Murphy 2012; János and Elza 2008

2 Methodology

2.1 Life-Cycle Assessment

According to International Organization for Standardization 14000 (ISO 2006),

there are four phases of an LCA procedure, including (1) the goal, scope definition,

and functional unit, (2) inventory analysis, (3) impact assessment, and (4) inter-

pretation. An LCA provides systematic view and complete assessment of a product

throughout its life cycle (Payraudeau et al. 2007). It is important to consider the

whole life cycle due to efficient energy management of renewable sources and

their GHG emissions. The scientific community considers LCA as one of the best

method for calculating the environmental burden associated with bioenergy pro-

duction (Consoli et al. 1993). The renewable directive (EC 2009) has provided

guidelines for the LCA of biofuels. An LCA of biofuels must evaluate GHG