Page 266 - Lindens Handbook of Batteries

P. 266

11.4 pRIMARy BATTERIES

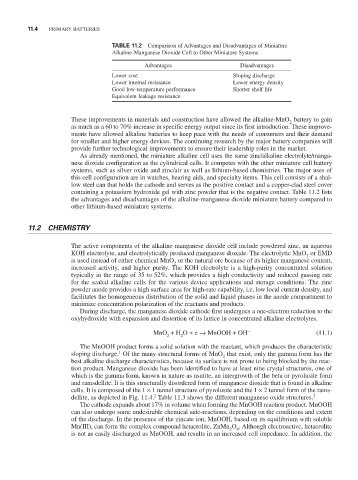

TABLE 11.2 Comparison of Advantages and Disadvantages of Miniature

Alkaline-Manganese Dioxide Cell to Other Miniature Systems

Advantages Disadvantages

Lower cost Sloping discharge

Lower internal resistance Lower energy density

Good low-temperature performance Shorter shelf life

Equivalent leakage resistance

These improvements in materials and construction have allowed the alkaline-MnO battery to gain

2

as much as a 60 to 70% increase in specific energy output since its first introduction. These improve-

ments have allowed alkaline batteries to keep pace with the needs of consumers and their demand

for smaller and higher energy devices. The continuing research by the major battery companies will

provide further technological improvements to ensure their leadership roles in the market.

As already mentioned, the miniature alkaline cell uses the same zinc/alkaline electrolyte/manga-

nese dioxide configuration as the cylindrical cells. It competes with the other miniature cell battery

systems, such as silver oxide and zinc/air as well as lithium-based chemistries. The major uses of

this cell configuration are in watches, hearing aids, and specialty items. This cell consists of a shal-

low steel can that holds the cathode and serves as the positive contact and a copper-clad steel cover

containing a potassium hydroxide gel with zinc powder that is the negative contact. Table 11.2 lists

the advantages and disadvantages of the alkaline-manganese dioxide miniature battery compared to

other lithium-based miniature systems.

11.2 CHEmISTRy

The active components of the alkaline-manganese dioxide cell include powdered zinc, an aqueous

KOH electrolyte, and electrolytically produced manganese dioxide. The electrolytic MnO or EMD

2

is used instead of either chemical MnO or the natural ore because of its higher manganese content,

2

increased activity, and higher purity. The KOH electrolyte is a high-purity concentrated solution

typically in the range of 35 to 52%, which provides a high conductivity and reduced gassing rate

for the sealed alkaline cells for the various device applications and storage conditions. The zinc

powder anode provides a high surface area for high-rate capability, i.e, low local current density, and

facilitates the homogeneous distribution of the solid and liquid phases in the anode compartment to

minimize concentration polarization of the reactants and products.

During discharge, the manganese dioxide cathode first undergoes a one-electron reduction to the

oxyhydroxide with expansion and distortion of its lattice in concentrated alkaline electrolytes.

-

MnO + H O + e → MnOOH + OH (11.1)

2

2

The MnOOH product forms a solid solution with the reactant, which produces the characteristic

sloping discharge. Of the many structural forms of MnO that exist, only the gamma form has the

1

2

best alkaline discharge characteristics, because its surface is not prone to being blocked by the reac-

tion product. Manganese dioxide has been identified to have at least nine crystal structures, one of

which is the gamma form, known in nature as nsutite, an intergrowth of the beta or pyrolusite form

and ramsdellite. It is this structurally disordered form of manganese dioxide that is found in alkaline

cells. It is composed of the 1 × 1 tunnel structure of pyrolusite and the 1 × 2 tunnel form of the rams-

dellite, as depicted in Fig. 11.4. Table 11.3 shows the different manganese oxide structures. 3

2

The cathode expands about 17% in volume when forming the MnOOH reaction product. MnOOH

can also undergo some undesirable chemical side-reactions, depending on the conditions and extent

of the discharge. In the presence of the zincate ion, MnOOH, based on its equilibrium with soluble

Mn(III), can form the complex compound hetaerolite, ZnMn O . Although electroactive, hetaerolite

2

4

is not as easily discharged as MnOOH, and results in an increased cell impedance. In addition, the