Page 303 - MEMS and Microstructures in Aerospace Applications

P. 303

Osiander / MEMS and microstructures in Aerospace applications DK3181_c013 Final Proof page 296 1.9.2005 12:45pm

296 MEMS and Microstructures in Aerospace Applications

each mission to provide a contamination control plan (CCP), which defines the

comprehensive contamination control program that will be implemented in the

mission. Additionally, specific verification plans and requirements must be defined

in the CCP.

Regardless of contamination sensitivity, the implementation of the CCP needs

to be addressed in all mission phases in order to prevent any detrimental contam-

ination damage. Among spacecraft systems, performance of optical and thermal

control is most vulnerable to contamination degradation. A high contamination

sensitivity mission is primarily one which relies on optical sensing, and imaging

or spacecraft or both, which require very strict temperature control, while a low

contamination sensitivity mission is generally one with very insensitive optics and

relatively flexible thermal control requirements. Highly sensitive missions usually

require design and implementation of a strict contamination control program ac-

companied with ongoing monitoring and cleaning procedures.

Table 13.1 describes top-level contamination requirements of high contamin-

ation-sensitive hardware in a conventional mission. As hardware dimensions

decrease due to spacecraft miniaturization, surface cleanliness levels become

increasingly significant. Micrometer-sized particles of lesser impact on conven-

tional spacecraft become extremely critical for miniaturized spacecraft.

13.6.2 MEMS CONTAMINATION CONTROL

The contamination effect on MEMS devices is enhanced by the relative dimensions

between contaminants and MEMS devices. Because MEMS devices may contain

exposed moving parts, they do not function well in the presence of liquid, vapor,

particles, or other contaminants. A contamination assessment needs to be made

early in the program to determine whether the possibility exists that the MEMS

devices will be unacceptably degraded by molecular or particulate contaminants, or

if it will be a source of contaminants itself. This preliminary assessment can be

achieved by carefully examining mission-specific environments and contamination

sources are shown in Table 13.2. The assessment should take into account all the

various factors during the entire mission phases including selection of materials

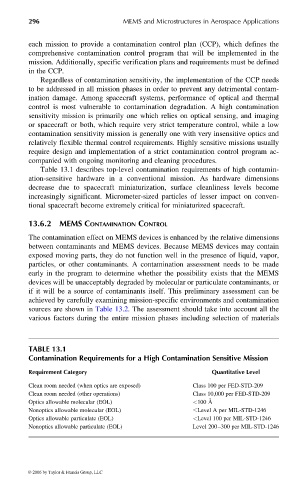

TABLE 13.1

Contamination Requirements for a High Contamination Sensitive Mission

Requirement Category Quantitative Level

Clean room needed (when optics are exposed) Class 100 per FED-STD-209

Clean room needed (other operations) Class 10,000 per FED-STD-209

Optics allowable molecular (EOL) <100 A ˚

Nonoptics allowable molecular (EOL) Level A per MIL-STD-1246

Optics allowable particulate (EOL) <Level 100 per MIL-STD-1246

Nonoptics allowable particulate (EOL) Level 200–300 per MIL-STD-1246

© 2006 by Taylor & Francis Group, LLC