Page 74 - Making things move_ DIY mechanisms for inventors, hobbyists, and artists

P. 74

Chapter 3 Screw It or Glue It: Fastening and Joining Parts 55

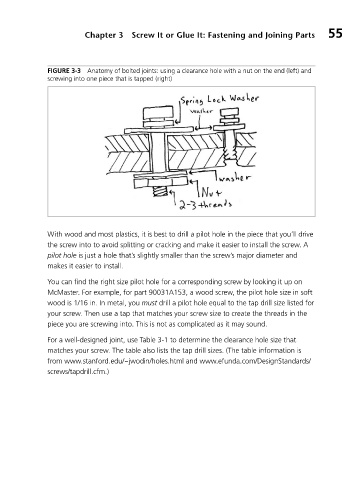

FIGURE 3-3 Anatomy of bolted joints: using a clearance hole with a nut on the end (left) and

screwing into one piece that is tapped (right)

With wood and most plastics, it is best to drill a pilot hole in the piece that you’ll drive

the screw into to avoid splitting or cracking and make it easier to install the screw. A

pilot hole is just a hole that’s slightly smaller than the screw’s major diameter and

makes it easier to install.

You can find the right size pilot hole for a corresponding screw by looking it up on

McMaster. For example, for part 90031A153, a wood screw, the pilot hole size in soft

wood is 1/16 in. In metal, you must drill a pilot hole equal to the tap drill size listed for

your screw. Then use a tap that matches your screw size to create the threads in the

piece you are screwing into. This is not as complicated as it may sound.

For a well-designed joint, use Table 3-1 to determine the clearance hole size that

matches your screw. The table also lists the tap drill sizes. (The table information is

from www.stanford.edu/~jwodin/holes.html and www.efunda.com/DesignStandards/

screws/tapdrill.cfm.)