Page 591 - Manufacturing Engineering and Technology - Kalpakjian, Serope : Schmid, Steven R.

P. 591

572 Chapter 21 Fundamentals of Machining

° Increased heat causes uneven dimensional changes in the part being machined,

making it difficult to control its dimensional accuracy and tolerances.

° An excessive temperature rise can induce thermal damage and metallurgical

changes in the machined surface, adversely affecting its properties.

From the preceding sections, it can be seen that the main sources of heat in ma-

chining are: (a) the work done in shearing in the primary shear zone, (b) energy dissi-

pated as friction at the tool-chip interface, and (c) heat generated as the tool rubs

against the machined surface, especially for dull or worn tools. Much effort has been

expended in establishing relationships among temperature and various material and

process variables in cutting. A comprehensive expression for the mean temperature,

Tmean, in orthogonal cutting is

= __1__ 3 V

0 0oo665Y

T pc _L , ( 21.19 3)

K0

where the mean temperature is in K, Yf is the flow stress in MPa, pc is the volumet-

ric specific heat in k]/m3 - K and K is the thermal diffusivity (ratio of thermal con-

2

ductivity to volumetric specific heat) in m /s. Because the material parameters in this

equation depend on temperature, it is important to use appropriate values that are

compatible with the predicted temperature range. It can be seen from Eq. (21.19a)

that the mean cutting temperature increases with workpiece strength, cutting speed,

and depth of cut, and decreases with increasing specific heat and thermal conduc-

tivity of the workpiece material.

An expression for the mean temperature in turning on a lathe is given by

Tmean ‘X V“fb, <21-19b)

where V is the cutting speed and f is the feed of the tool, as shown in Fig. 21.2.

Approximate values of the exponents a and b are a = 0.2 and b = 0.125 for

carbide tools and a = 0.5 and b = 0.375 for high-speed steel tools.

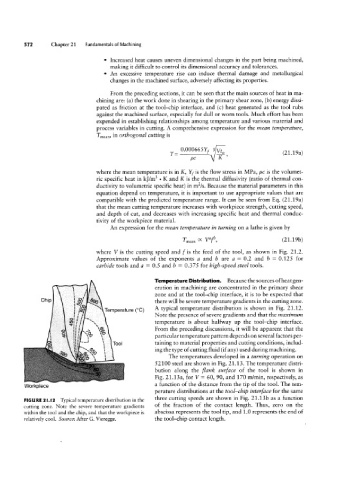

Temperature Distribution. Because the sources of heat gen-

eration in machining are concentrated in the primary shear

zone and at the tool-chip interface, it is to be expected that

Chip there will be severe temperature gradients in the cutting zone.

Temperature (OC) A typical temperature distribution is shown in Fig. 21.12.

Note the presence of severe gradients and that the maximum

temperature is about halfway up the tool-chip interface.

From the preceding discussions, it will be apparent that the

particular temperature pattern depends on several factors per-

Tool taining to material properties and cutting conditions, includ-

ing the type of cutting fluid (if any) used during machining.

The temperatures developed in a turning operation on

52100 steel are shown in Fig. 21.13. The temperature distri-

bution along the flank surface of the tool is shown in

Fig. 21.13a, for V = 60, 90, and 170 m/min, respectively, as

a function of the distance from the tip of the tool. The tem-

Workpiece

perature distributions at the tool-chip interface for the same

FIGURE 2l.l2 Typical temperature distribution in the three cutting speeds are shown in Fig. 21.13b as a function

Cutting Zong Note the Severe temperature gradients of the fraction of the contact length. Thus, zero on the

within the tool and the chip, and that the workpiece is abscissa represents the tool tip, and 1.0 represents the end of

relatively cool. Source: After G. Vieregge. the tool-chip contact length.