Page 94 - Manufacturing Engineering and Technology - Kalpakjian, Serope : Schmid, Steven R.

P. 94

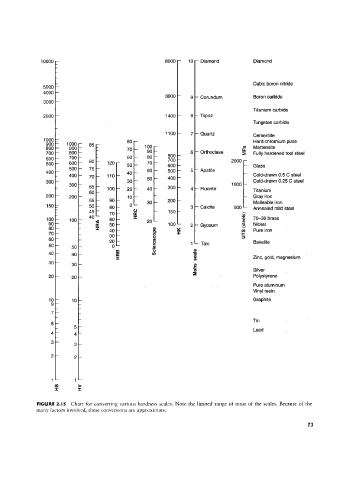

1 0000 8000 Diamond Diamond

Cubic boron nitride

5000

4000 9_

3000 Corundum Boron carbide

3000

Titanium carbide

8_

2000 1400 Topaz

Tungsten carbide

7-

1100 Quartz Cementite

1 000 Hard chromium plate

900 1 000

800 900 100 6- D. cc Martensite

700 800 90 E 800 Orthoclase E Fully hardened tool steel

600 700 700 2000

500 600 600 Glass

500 5_

400 500 Apatite

400 Cold-drawn 0.5 C steel

400

300 Cold-drawn 0.25 C steel

300 4- 1000

40‘“ 300 Fluorite Titanium

200 200 Gray iron

200 Malleable iron

150 3_. Calcite 500 Annealed mild steel

150

1 00 100 70-30 brass

90 100 Gypsum Nickel

80

Pure iron

70

so

50 “ 50 Talc Bakelite

40 40

Zinc, gold, magnesium

3° 30

20' 20 Silver

Polystyrene

Pure aluminum

Vinyl resin

10 10 Graphite

9

7

Tin

5

5

Lead

4 4

3 3

2 2

1 1

I I

m >

EE

II!

dr:

as

gm

§;

N

5.

WUI

QQ

SD

§_.:

1.5"

gli

F1

30

gi

:xii

§C.'.

CS

50°

35

wa,

NO

R§

$5

*ia

O

5_2

l ga

Scleroscope

2%

FH;

FD

Y’

Z

af

f'f

R' MohsI

scale

3

a

Q-

S

I3

UO

FD

O

*N

Q

(steels)

UTS C/1

FT

O

"fx

F?

D'

(D

V1

O

&

FD

E”

UU

FD

O

SD

CI

V)

FD

O

"N

f'f

IT

FD