Page 194 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 194

Section 7.2 The Structure of Polymers

H ill s * ` i f if C

Plasticizers

Stabilizers 3

Colorants ""} I

ren

Flame retardants

Lubricants

_ _ gg ` i t'i "i" ` ` ' : I _ Thermop|astics:Acrylics, ABS, nylons

Heat, PV€‘SSUfe»

polycarbonates, polyethylenes

polyvinyl chloride etc

Kjéfgr `ii

mars

Polymer

<rrri” “ ~

Catalyst

Thermosets:Epoxies,phenolics

ee <rr»

polyimides, etc.

i :

' |

|:>O|ymeliZatiOn; Amoréhous E Elastomers: Natural and synthetic rubbers

Condengatign, Pamy Crystamne : silicones, polyurethanes etc

a°ld'l'°“ Linear Cross-linking

Branched

Homopolymer

Copolymer

Terpolymer

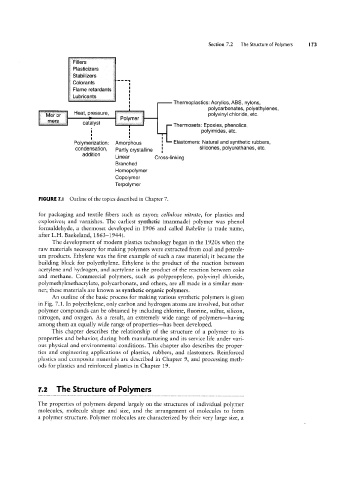

FIGURE 1.l Outline of the topics described in Chapter 7.

for packaging and textile fibers such as rayon; cellulose nitrate, for plastics and

explosives; and varnishes. The earliest synthetic (manmade) polymer was phenol

formaldehyde, a thermoset developed in 1906 and called Bakelite (a trade name,

after L.H. Baekeland, 1863-1944).

The development of modern plastics technology began in the 1920s when the

raw materials necessary for making polymers were extracted from coal and petrole-

um products. Ethylene was the first example of such a raw material; it became the

building block for polyethylene. Ethylene is the product of the reaction between

acetylene and hydrogen, and acetylene is the product of the reaction between coke

and methane. Commercial polymers, such as polypropylene, polyvinyl chloride,

polymethylmethacrylate, polycarbonate, and others, are all made in a similar man-

ner; these materials are known as synthetic organic polymers.

An outline of the basic process for making various synthetic polymers is given

in Fig. 7.1. In polyethylene, only carbon and hydrogen atoms are involved, but other

polymer compounds can be obtained by including chlorine, fluorine, sulfur, silicon,

nitrogen, and oxygen. As a result, an extremely wide range of polymers--having

among them an equally wide range of properties-has been developed.

This chapter describes the relationship of the structure of a polymer to its

properties and behavior, during both manufacturing and its service life under vari-

ous physical and environmental conditions. This chapter also describes the proper-

ties and engineering applications of plastics, rubbers, and elastomers. Reinforced

plastics and composite materials are described in Chapter 9, and processing meth-

ods for plastics and reinforced plastics in Chapter 19.

7.2 The Structure of Polymers

The properties of polymers depend largely on the structures of individual polymer

molecules, molecule shape and size, and the arrangement of molecules to form

a polymer structure. Polymer molecules are characterized by their very large size, a