Page 331 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 331

3I0 Chapter 12 Metal Casting: Design, Materials, and Economics

l2.I4. Note in Fig. 12.4 that the ductility of some cast |2.| 9. Explain Why the elastic modulus, E, of gray cast iron

alloys is very low. Do you think that this should be a sig- varies so widely, as shown in Table 12.4.

nificant concern in engineering applications of castings? l2.20. If you were to incorporate lettering or numbers on a

Explain. sand-cast part, would you make them protrude from the

l2.l5. Do you think that there will be fewer defects in a surface or recess them into the surface? What if the part were

casting made by gravity pouring versus one made by pouring to be made by investment casting? Explain your answer.

under pressure? Explain. l2.2|. The general design recommendations for a well in

l2.l6. Explain the difference in the importance of drafts in sand casting (see Fig. 11.3) are that (a) its diameter should be

green-sand casting versus permanent-mold casting. at least twice the exit diameter of the sprue and (b) its depth

should be approximately twice the depth of the runner.

I2.I 7. What type of cast iron would be suitable for heavy-

machine bases, such as presses and machine tools? Why? Explain the consequences of deviating from these guidelines.

l2.l8. Explain the advantages and limitations of sharp and l2.22. The heavy regions of parts typically are placed in the

drag in sand casting and not in the cope. Explain why.

rounded fillets, respectively, in casting design.

QUANTITATIVE PROBLEMS

I] |2.23. When designing patterns for casting, patternmak- l2.24. Using the data given in Table 12.2, develop approxi-

ers use special rulers that automatically incorporate solid mate plots of (a) castability versus weldability and (b) Casta-

shrinkage allowances into their designs. For example, a bility versus machinability, for at least five of the materials

300-mm patternmaker’s ruler is longer than 300 mm. How listed in the table.

long should a patternmaker’s ruler be for making patterns for

(a) aluminum castings and (b) high-manganese steel?

SYNTHESIS, DESIGN, AND PROIECTS

l2.25. Describe the general design considerations pertaining and (d) chills may be used to help feed molten metal and elim-

to metal casting. inate porosity in the isolated hub boss.

|2.26. Add more examples to those shown in Fig. 12.2. l2.32. Assume that the introduction to this chapter is miss-

l2.27. Explain how ribs and serrations are helpful in cast- ing. Write a brief introduction to highlight the importance of

ing flat surfaces that otherwise may warp. Give a specific the topics covered in it.

illustration. ll l2.33. In Fig. P12.33, the original casting design shown

l2.28. List casting processes that are suitable for making in (a) was resized and modified to incorporate ribs in the

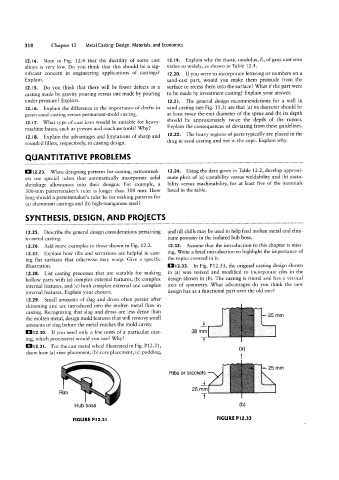

hollow parts with (a) complex external features, (b) complex design shown in (b). The casting is round and has a vertical

internal features, and (c) both complex external and complex axis of symmetry. What advantages do you think the new

internal features. Explain your choices. design has as a functional part over the old one?

l2.29. Small amounts of slag and dross often persist after

skimming and are introduced into the molten metal flow in

casting. Recognizing that slag and dross are less dense than

the molten metal, design mold features that will remove small 25 mm

amounts of slag before the metal reaches the mold cavity.

|] l2.30. If you need only a few units of a particular cast- 38 mm

ing, which process(es) would you use? Why?

|] I2.3 I. For the cast metal wheel illustrated in Fig. P12.31,

(H)

show how (a) riser placement, (b) core placement, (c) padding,

25 mm

Ribs or brackets

Hub boss (D)

FIGURE PI2.3l neun: |>|z.:s