Page 26 - Mechanical Behavior of Materials

P. 26

Section 1.2 Types of Material Failure 25

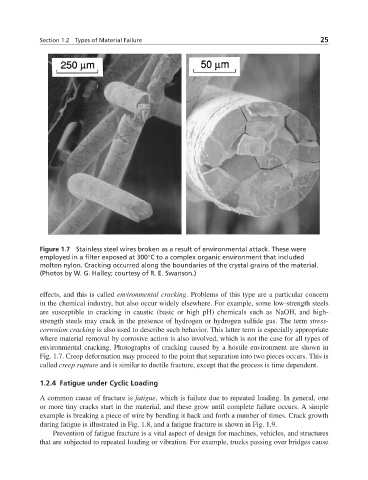

Figure 1.7 Stainless steel wires broken as a result of environmental attack. These were

◦

employed in a filter exposed at 300 C to a complex organic environment that included

molten nylon. Cracking occurred along the boundaries of the crystal grains of the material.

(Photos by W. G. Halley; courtesy of R. E. Swanson.)

effects, and this is called environmental cracking. Problems of this type are a particular concern

in the chemical industry, but also occur widely elsewhere. For example, some low-strength steels

are susceptible to cracking in caustic (basic or high pH) chemicals such as NaOH, and high-

strength steels may crack in the presence of hydrogen or hydrogen sulfide gas. The term stress-

corrosion cracking is also used to describe such behavior. This latter term is especially appropriate

where material removal by corrosive action is also involved, which is not the case for all types of

environmental cracking. Photographs of cracking caused by a hostile environment are shown in

Fig. 1.7. Creep deformation may proceed to the point that separation into two pieces occurs. This is

called creep rupture and is similar to ductile fracture, except that the process is time dependent.

1.2.4 Fatigue under Cyclic Loading

A common cause of fracture is fatigue, which is failure due to repeated loading. In general, one

or more tiny cracks start in the material, and these grow until complete failure occurs. A simple

example is breaking a piece of wire by bending it back and forth a number of times. Crack growth

during fatigue is illustrated in Fig. 1.8, and a fatigue fracture is shown in Fig. 1.9.

Prevention of fatigue fracture is a vital aspect of design for machines, vehicles, and structures

that are subjected to repeated loading or vibration. For example, trucks passing over bridges cause