Page 229 - Mechanical Engineers' Handbook (Volume 4)

P. 229

218 Furnaces

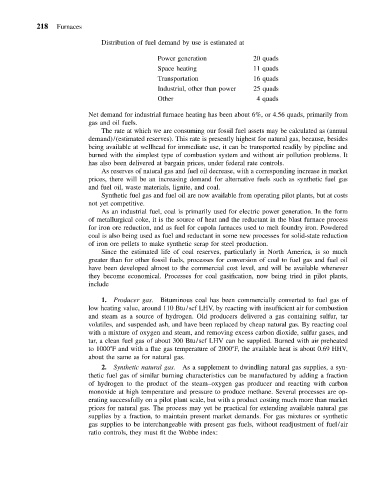

Distribution of fuel demand by use is estimated at

Power generation 20 quads

Space heating 11 quads

Transportation 16 quads

Industrial, other than power 25 quads

Other 4 quads

Net demand for industrial furnace heating has been about 6%, or 4.56 quads, primarily from

gas and oil fuels.

The rate at which we are consuming our fossil fuel assets may be calculated as (annual

demand)/(estimated reserves). This rate is presently highest for natural gas, because, besides

being available at wellhead for immediate use, it can be transported readily by pipeline and

burned with the simplest type of combustion system and without air pollution problems. It

has also been delivered at bargain prices, under federal rate controls.

As reserves of natural gas and fuel oil decrease, with a corresponding increase in market

prices, there will be an increasing demand for alternative fuels such as synthetic fuel gas

and fuel oil, waste materials, lignite, and coal.

Synthetic fuel gas and fuel oil are now available from operating pilot plants, but at costs

not yet competitive.

As an industrial fuel, coal is primarily used for electric power generation. In the form

of metallurgical coke, it is the source of heat and the reductant in the blast furnace process

for iron ore reduction, and as fuel for cupola furnaces used to melt foundry iron. Powdered

coal is also being used as fuel and reductant in some new processes for solid-state reduction

of iron ore pellets to make synthetic scrap for steel production.

Since the estimated life of coal reserves, particularly in North America, is so much

greater than for other fossil fuels, processes for conversion of coal to fuel gas and fuel oil

have been developed almost to the commercial cost level, and will be available whenever

they become economical. Processes for coal gasification, now being tried in pilot plants,

include

1. Producer gas. Bituminous coal has been commercially converted to fuel gas of

low heating value, around 110 Btu/scf LHV, by reacting with insufficient air for combustion

and steam as a source of hydrogen. Old producers delivered a gas containing sulfur, tar

volatiles, and suspended ash, and have been replaced by cheap natural gas. By reacting coal

with a mixture of oxygen and steam, and removing excess carbon dioxide, sulfur gases, and

tar, a clean fuel gas of about 300 Btu/scf LHV can be supplied. Burned with air preheated

to 1000 F and with a flue gas temperature of 2000 F, the available heat is about 0.69 HHV,

about the same as for natural gas.

2. Synthetic natural gas. As a supplement to dwindling natural gas supplies, a syn-

thetic fuel gas of similar burning characteristics can be manufactured by adding a fraction

of hydrogen to the product of the steam–oxygen gas producer and reacting with carbon

monoxide at high temperature and pressure to produce methane. Several processes are op-

erating successfully on a pilot plant scale, but with a product costing much more than market

prices for natural gas. The process may yet be practical for extending available natural gas

supplies by a fraction, to maintain present market demands. For gas mixtures or synthetic

gas supplies to be interchangeable with present gas fuels, without readjustment of fuel/air

ratio controls, they must fit the Wobbe index: