Page 273 - Mechanical Engineers' Handbook (Volume 4)

P. 273

262 Furnaces

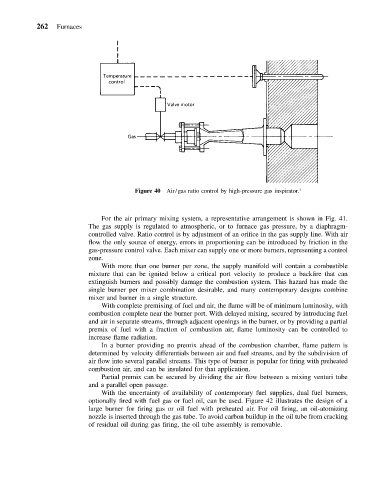

Figure 40 Air/gas ratio control by high-pressure gas inspirator. 1

For the air primary mixing system, a representative arrangement is shown in Fig. 41.

The gas supply is regulated to atmospheric, or to furnace gas pressure, by a diaphragm-

controlled valve. Ratio control is by adjustment of an orifice in the gas supply line. With air

flow the only source of energy, errors in proportioning can be introduced by friction in the

gas-pressure control valve. Each mixer can supply one or more burners, representing a control

zone.

With more than one burner per zone, the supply manifold will contain a combustible

mixture that can be ignited below a critical port velocity to produce a backfire that can

extinguish burners and possibly damage the combustion system. This hazard has made the

single burner per mixer combination desirable, and many contemporary designs combine

mixer and burner in a single structure.

With complete premixing of fuel and air, the flame will be of minimum luminosity, with

combustion complete near the burner port. With delayed mixing, secured by introducing fuel

and air in separate streams, through adjacent openings in the burner, or by providing a partial

premix of fuel with a fraction of combustion air, flame luminosity can be controlled to

increase flame radiation.

In a burner providing no premix ahead of the combustion chamber, flame pattern is

determined by velocity differentials between air and fuel streams, and by the subdivision of

air flow into several parallel streams. This type of burner is popular for firing with preheated

combustion air, and can be insulated for that application.

Partial premix can be secured by dividing the air flow between a mixing venturi tube

and a parallel open passage.

With the uncertainty of availability of contemporary fuel supplies, dual fuel burners,

optionally fired with fuel gas or fuel oil, can be used. Figure 42 illustrates the design of a

large burner for firing gas or oil fuel with preheated air. For oil firing, an oil-atomizing

nozzle is inserted through the gas tube. To avoid carbon buildup in the oil tube from cracking

of residual oil during gas firing, the oil tube assembly is removable.