Page 41 - Singiresu S. Rao-Mechanical Vibrations in SI Units, Global Edition-Pearson (2017)

P. 41

38 Chapter 1 Fundamentals oF Vibration

Overarm

Arbor

Arbor support

Column

Cutter

Table

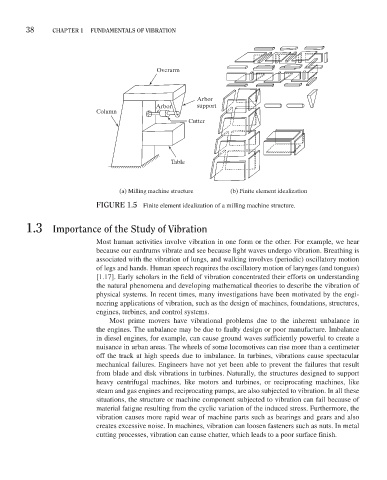

(a) Milling machine structure (b) Finite element idealization

FiGure 1.5 Finite element idealization of a milling machine structure.

1.3 importance of the study of Vibration

Most human activities involve vibration in one form or the other. For example, we hear

because our eardrums vibrate and see because light waves undergo vibration. Breathing is

associated with the vibration of lungs, and walking involves (periodic) oscillatory motion

of legs and hands. Human speech requires the oscillatory motion of larynges (and tongues)

[1.17]. Early scholars in the field of vibration concentrated their efforts on understanding

the natural phenomena and developing mathematical theories to describe the vibration of

physical systems. In recent times, many investigations have been motivated by the engi-

neering applications of vibration, such as the design of machines, foundations, structures,

engines, turbines, and control systems.

Most prime movers have vibrational problems due to the inherent unbalance in

the engines. The unbalance may be due to faulty design or poor manufacture. Imbalance

in diesel engines, for example, can cause ground waves sufficiently powerful to create a

nuisance in urban areas. The wheels of some locomotives can rise more than a centimeter

off the track at high speeds due to imbalance. In turbines, vibrations cause spectacular

mechanical failures. Engineers have not yet been able to prevent the failures that result

from blade and disk vibrations in turbines. Naturally, the structures designed to support

heavy centrifugal machines, like motors and turbines, or reciprocating machines, like

steam and gas engines and reciprocating pumps, are also subjected to vibration. In all these

situations, the structure or machine component subjected to vibration can fail because of

material fatigue resulting from the cyclic variation of the induced stress. Furthermore, the

vibration causes more rapid wear of machine parts such as bearings and gears and also

creates excessive noise. In machines, vibration can loosen fasteners such as nuts. In metal

cutting processes, vibration can cause chatter, which leads to a poor surface finish.