Page 21 - Mechatronic Systems Modelling and Simulation with HDLs

P. 21

10 2 PRINCIPLES OF MODELLING AND SIMULATION

Specification ? System

Abstraction Module 1

Submodule 1

Time

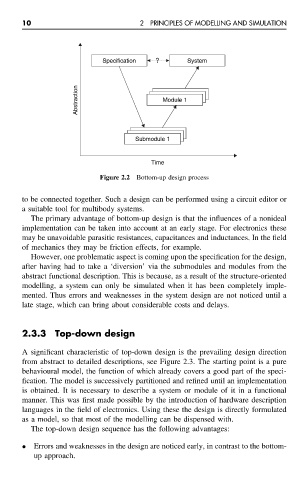

Figure 2.2 Bottom-up design process

to be connected together. Such a design can be performed using a circuit editor or

a suitable tool for multibody systems.

The primary advantage of bottom-up design is that the influences of a nonideal

implementation can be taken into account at an early stage. For electronics these

may be unavoidable parasitic resistances, capacitances and inductances. In the field

of mechanics they may be friction effects, for example.

However, one problematic aspect is coming upon the specification for the design,

after having had to take a ‘diversion’ via the submodules and modules from the

abstract functional description. This is because, as a result of the structure-oriented

modelling, a system can only be simulated when it has been completely imple-

mented. Thus errors and weaknesses in the system design are not noticed until a

late stage, which can bring about considerable costs and delays.

2.3.3 Top-down design

A significant characteristic of top-down design is the prevailing design direction

from abstract to detailed descriptions, see Figure 2.3. The starting point is a pure

behavioural model, the function of which already covers a good part of the speci-

fication. The model is successively partitioned and refined until an implementation

is obtained. It is necessary to describe a system or module of it in a functional

manner. This was first made possible by the introduction of hardware description

languages in the field of electronics. Using these the design is directly formulated

as a model, so that most of the modelling can be dispensed with.

The top-down design sequence has the following advantages:

• Errors and weaknesses in the design are noticed early, in contrast to the bottom-

up approach.